Wholesale Crucible For Electron Beam Evaporation - Molybdenum Evaporation Boats For Pvd Coating – WINNERS

Wholesale Crucible For Electron Beam Evaporation - Molybdenum Evaporation Boats For Pvd Coating – WINNERS Detail:

Product Description

In terms of physical and chemical properties, molybdenum boats generally have the characteristics of high density, high melting point, high strength, low thermal expansion coefficient, high temperature resistance, corrosion resistance, good creep resistance, ductility and electrical and thermal conductivity. There are certain differences in the specific physical and chemical properties and uses of molybdenum boats made of different materials. The temperature that pure molybdenum boats can withstand is around 1100°C. According to different shapes, molybdenum boats have round, rectangular, square and trapezoidal shapes; according to different processing methods, molybdenum boats can be divided into punching boats, folding boats, welding boats and riveting boats; It can be divided into pure molybdenum boat, molybdenum lanthanum boat, molybdenum zirconium titanium boat, molybdenum rhenium boat, tungsten molybdenum boat and so on.

Product Parameters

|

Products name |

Molybdenum boats |

|

Material |

Mo1, MoLa, MoRe |

|

Density |

10.2g/cm³ |

|

Purity |

≥99.95% |

|

Technology |

Riveting, Stamping, etc. |

|

Application |

PVD Coating |

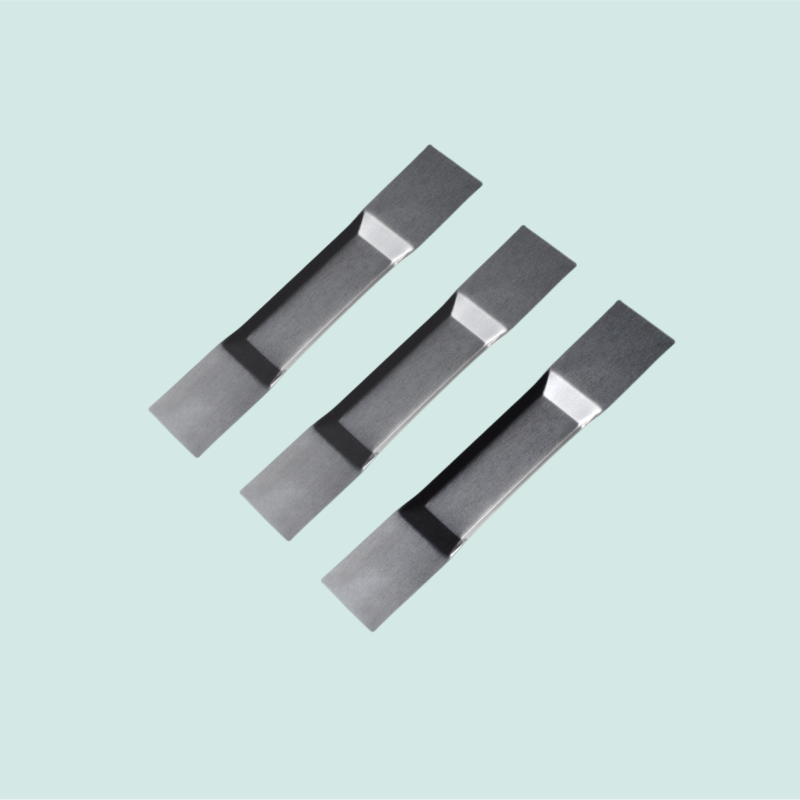

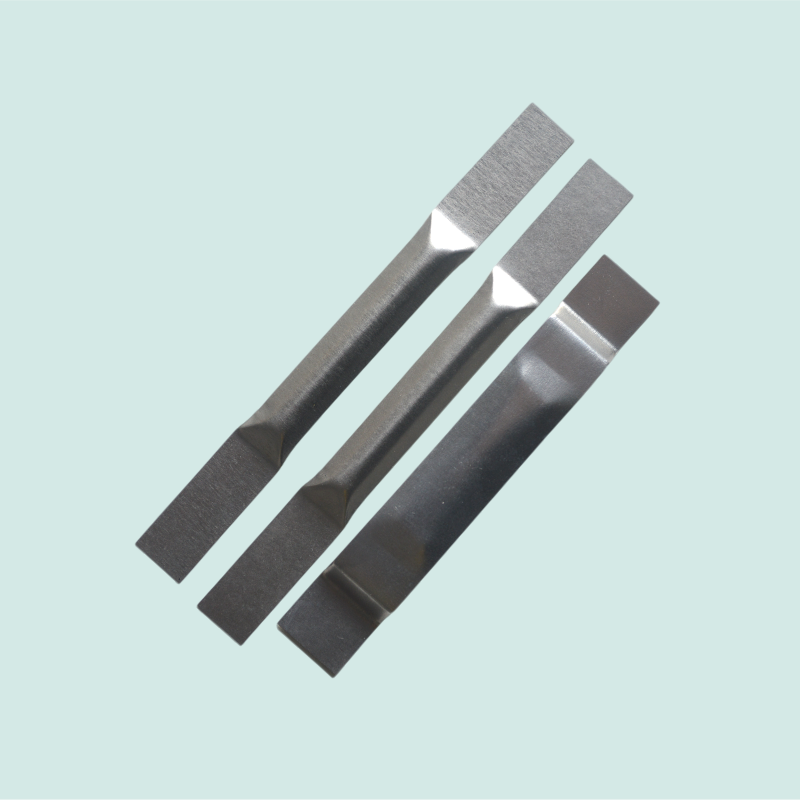

Common Classification Of Molybdenum Boat

1. Flat groove molybdenum boat: suitable for high wettability materials.

2. V-shaped groove molybdenum boat: suitable for materials with less wettability.

3. Oval grooved molybdenum boat: suitable for materials in molten state.

4. Spherical groove molybdenum boat: suitable for expensive materials such as gold and silver.

5. Narrow slot molybdenum boat: This design prevents the vapor deposition material from sticking to the filament clip.

Application

● Coating technology (vacuum thermal evaporation).

● Electronic industry (capacitor sintering).

● Power engineering industry (nuclear fuel sintering) Order information.

Standard Size

|

Model |

Thickness (mm) |

Width(mm) |

Length(mm) |

|

#210 |

0.2 |

10 |

100 |

|

#215 |

0.2 |

15 |

100 |

|

#220 |

0.2 |

20 |

100 |

|

#310 |

0.3 |

10 |

100 |

|

#315 |

0.3 |

15 |

100 |

|

#320 |

0.3 |

20 |

100 |

|

#510 |

0.5 |

10 |

100 |

|

#515 |

0.5 |

15 |

100 |

Note: Special specifications and dimensions can be processed according to drawings or samples.

Order Information

Inquiries and orders should include the following information.

● Drawing or size.

● Surface: Alkali washed surface, electropolished surface.

● Quantity.

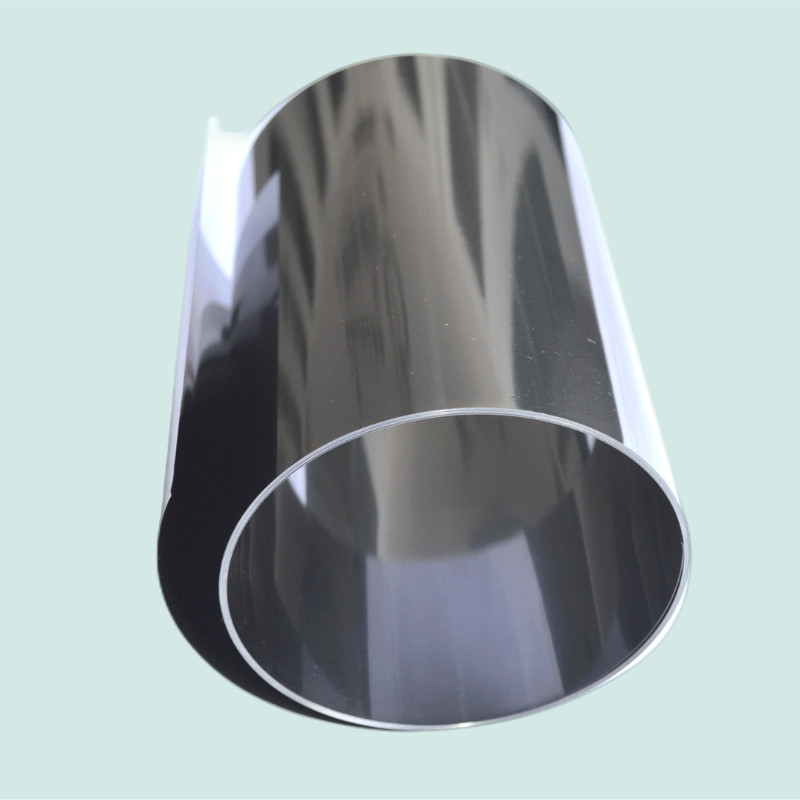

Product detail pictures:

Related Product Guide:

We have now a skilled, performance group to offer excellent support for our consumer. We usually follow the tenet of customer-oriented, details-focused for Wholesale Crucible For Electron Beam Evaporation - Molybdenum Evaporation Boats For Pvd Coating – WINNERS , The product will supply to all over the world, such as: Birmingham, Salt Lake City, Holland, Customer satisfaction is our first goal. Our mission is to pursue the superlative quality, making continual progress. We sincerely welcome you to make progress hand in hand with us, and construct a prosperous future together.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!