Vacuum Metallized Tungsten Filament Heater Manufacturer Customization

Vacuum Metallized Tungsten Filament Heater Manufacturer Customization,

Vacuum Metallized,

Tungsten Evaporation Filaments

A tungsten evaporation filament is a crucial component used in physical vapor deposition (PVD) processes, specifically in thermal evaporation. PVD is a technique employed for depositing thin films on various surfaces, and tungsten evaporation filaments play a key role in this process.

Tungsten filaments are widely used for thin film deposition of various metals and alloys. They are used to vaporize metal wire or foil that can be inserted into a coil of filament or a thin wire can be wound around the coil. The evaporation process involves melting metal to wet the filament coil and then increasing power to evaporate the molten metal. It can be used for thin film deposition of aluminum, as well as gold, silver, nickel, aluminum, titanium, and other metals.

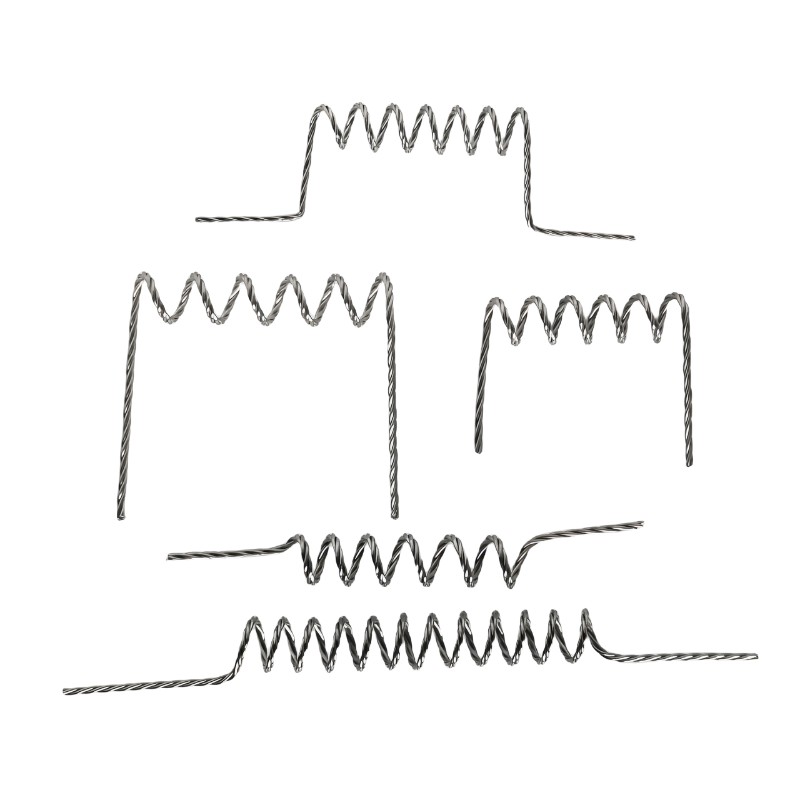

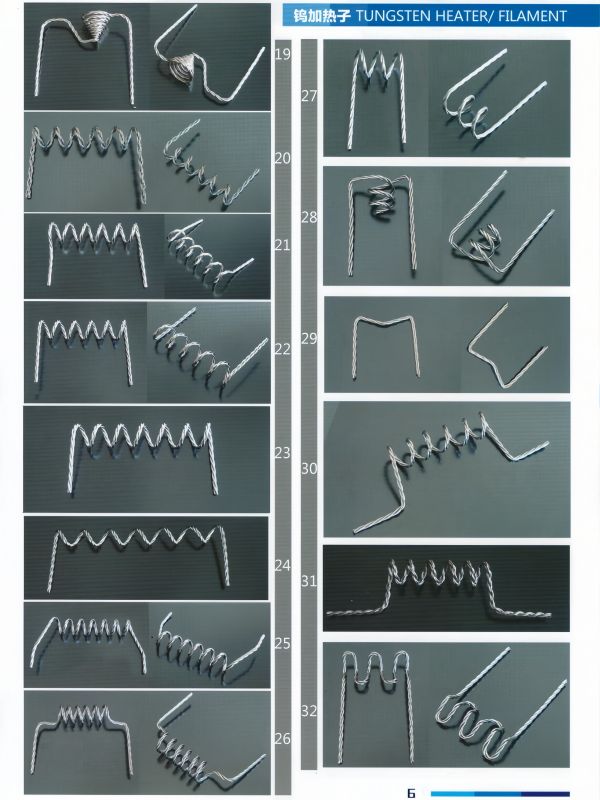

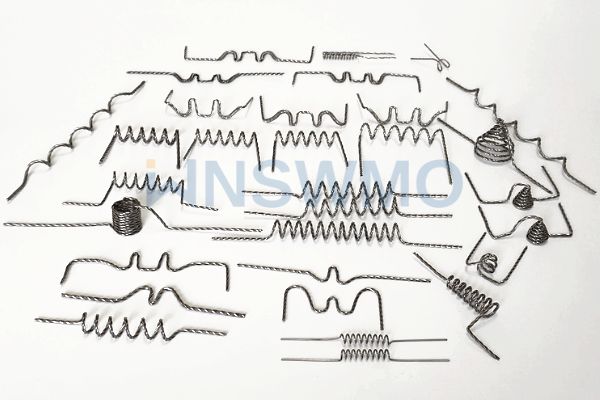

Tungsten evaporating coils are made of single-strand or multi-strand tungsten wire, which can be bent into various shapes according to installation or evaporation needs. We provide customers with various tungsten-stranded wire solutions, welcome to consult.

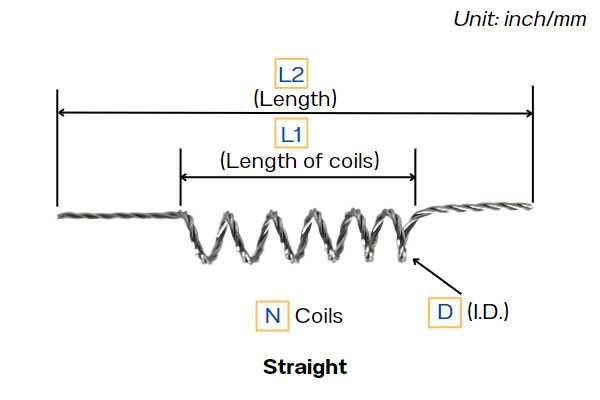

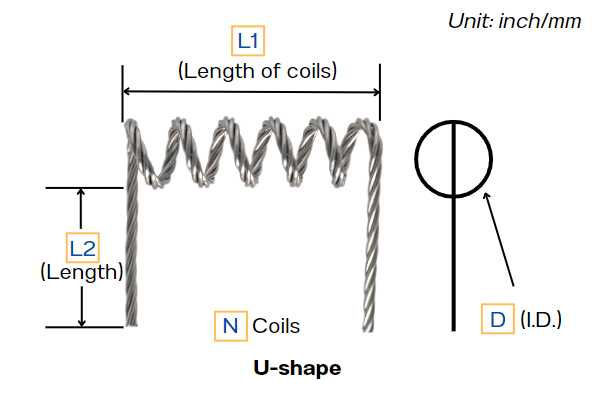

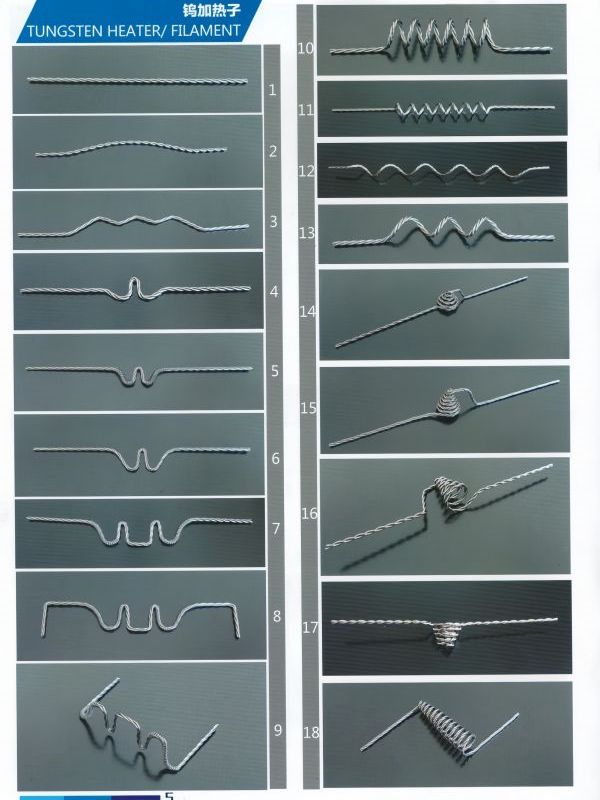

Tungsten Filaments Drawings

Tungsten Filament Drawings

Note: The drawing only shows straight and U-shaped filaments, allowing you to customize other types and sizes of tungsten spiral filaments, including peak-shaped filaments, etc.

|

Shape |

Straight / U-Shape, Can be customized |

|

Number of Strands |

1, 2, 3, 4 |

|

Coils |

4, 6, 8, 10 |

|

Diameter of Wires(mm) |

φ0.76, φ0.81, φ1 |

|

Length of Coils |

L1 |

|

Length |

L2 |

|

ID of Coils |

D |

|

Note: other specifications and filament shapes can be customized. |

|

Choose the tungsten filament that suits you, and we can customize it. The customization time is as short as 10 days, and the minimum order quantity is only 3 kg (wholesale price).

Applications of Tungsten Evaporation Filament

Tungsten evaporation filaments are valued for their high melting point, stability, and durability in high-temperature environments. The versatility of tungsten makes it a preferred material for filaments in various thin film deposition processes across industries. Here are some key areas where tungsten evaporation filaments find applications:

● Semiconductor Manufacturing

● Optical Coating

● Solar Cell Manufacturing

● Research and Development

● Decorative Coatings

● Vacuum Metallurgy

● Thin Film Deposition for Electronics

● Aerospace Industry

● Automotive Industry

What are the advantages of Tungsten Evaporation Filaments?

Classification of Tungsten Filament Heaters

● Coil Heaters

● Basket Heaters

● Spiral Heaters

● Point and Loop Heaters

We can provide various forms of Tungsten Thermal Filament Sources, you can learn about these products through our catalog, welcome to consult us.

View Tungsten Filament Catalog

We provide evaporation sources and evaporation materials for PVD coating & Optical coating, these products include:

| Electron Beam Crucible Liners | Tungsten Coil Heater | Tungsten Cathode Filament |

| Thermal Evaporation Crucible | Evaporation Material | Evaporation Boat |

Don’t have the product you need? Please contact us, we will solve it for you.

Payment & Shipping

→PaymentSupport T/T, PayPal, Alipay, WeChat Pay, etc. Please negotiate with us for other payment methods.

→ShippingSupport FedEx, DHL, UPS, sea freight, and air freight, you can customize your transportation plan, and we will also provide cheap transportation methods for your reference.

Do you want to know more about our products?

Contact Us

Amanda│Sales Manager

E-mail: amanda@winnersmetals.com

Phone: +86 156 1977 8518 (WhatsApp/ Wechat)

If you want to know more details and prices of our products, please contact our sales manager, she will reply to you as soon as possible (usually within 24 hours), of course, you can also click the “REQUEST A QUOTE” button, or contact us directly by email us(Email:info@winnersmetals.com).

Tungsten coil plays an indispensable role in vacuum metallization technology with its excellent high temperature resistance, excellent conductivity, outstanding mechanical strength and excellent corrosion resistance. Choosing tungsten coil means choosing an efficient, reliable and long-lasting solution to provide your products with higher added value and competitiveness.

We are committed to providing customers with the highest quality tungsten coil products to meet your various needs in the field of vacuum metallization. If you have any questions about our products or need further information, please feel free to contact us. Let us work together to promote the progress and development of industrial technology!