Tungsten twisted wire heater: the core advantage in the field of PVD coating

Tungsten twisted wire heater: the core advantage in the field of PVD coating,

Tungsten twisted wire heater: the core advantage in the field of PVD coating,

Tungsten (W) Evaporation Coils, Tungsten Heaters

The tungsten filament heater has the advantages of an extremely high melting point, excellent corrosion resistance and excellent material purity. It has high resistivity and low vapor pressure and is very suitable as an evaporation source. It is suitable for the evaporation of low melting point materials such as aluminum, indium, and tin.

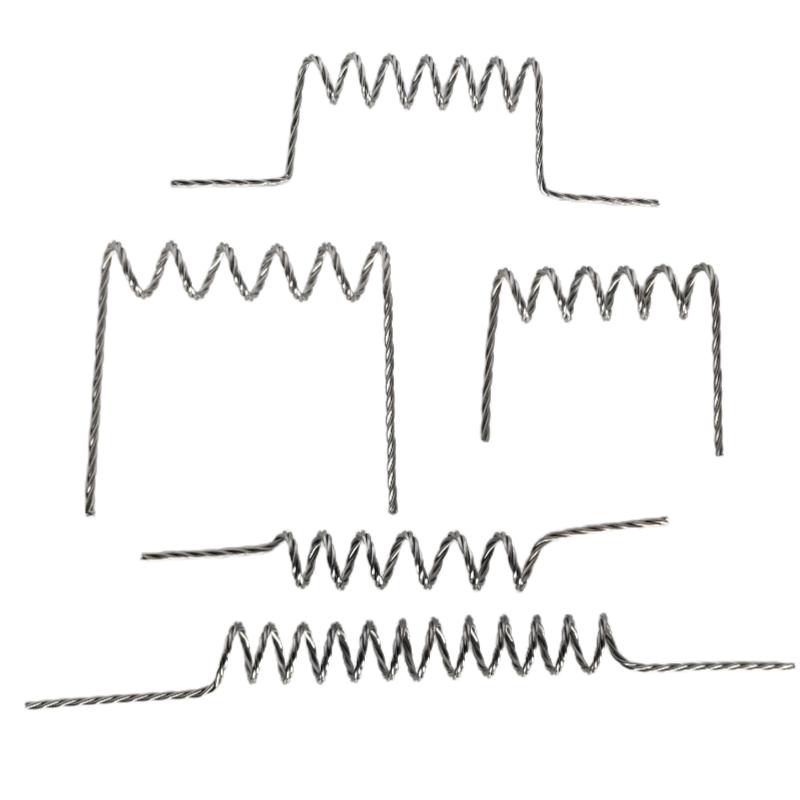

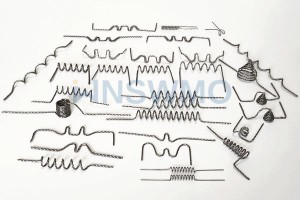

Tungsten evaporating coils are made of single-strand or multi-strand tungsten wire, which can be bent into various shapes according to installation or evaporation needs. We provide customers with various tungsten-stranded wire solutions, welcome to consult.

Tungsten Coil Information

| Product Name | Tungsten Coil Heater/Evaporation Coil |

| Purity | W≥99.95% |

| Density | 19.3g/cm³ |

| Melting Point | 3410°C |

| Strands | φ0.76X3, φ0.81X3, φ1.0X3, φ1.0X2, Can be customized. |

| MOQ | 3Kg |

| Application | Thermal Evaporation Coating |

Our Advantages

Our thermal filament tungsten heater has low energy consumption, long life and good evaporation effect, and is suitable for all kinds of vacuum evaporation machines.

Classification of Tungsten Filament Heaters

• Coil Heaters

• Basket Heaters

• Spiral Heaters

• Point and Loop Heaters

We can provide various forms of Tungsten Thermal Filament Sources, you can learn about these products through our catalog, welcome to consult us.

| Shape | Straight, U Shape, Can be customized |

| Number of Strands | 1, 2, 3, 4 |

| Coils | 4, 6, 8, 10 |

| Diameter of Wires(mm) | 0.76, 0.81, 1 |

| Length of Coils | L1 |

| Length | L2 |

| ID of Coils | D |

| Note: other specifications and filament shapes can be customized. | |

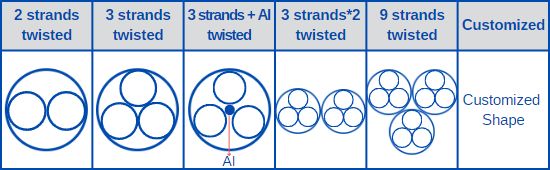

Stranded wire specification: φ0.76X3, φ0.81X3, φ1.0X3, φ1.0X2, φ0.81X4, φ0.81X3+Al, Can be customized.

We provide various tungsten wire stranding solutions to our customers.You can customize the required specifications and styles.

We provide evaporation sources and evaporation materials for PVD coating & Optical coating, these products include:

| Electron Beam Crucible Liners | Tungsten Coil Heater | Tungsten Cathode Filament |

| Thermal Evaporation Crucible | Evaporation Material | Evaporation Boat |

Don’t have the product you need? Please contact us, we will solve it for you.

Payment & Shipping

→PaymentSupport T/T, PayPal, Alipay, WeChat Pay, etc. Please negotiate with us for other payment methods.

→ShippingSupport FedEx, DHL, UPS, sea freight, and air freight, you can customize your transportation plan, and we will also provide cheap transportation methods for your reference.

Do you want to know more about our products?

Contact Me

Amanda│Sales Manager

E-mail: amanda@winnersmetals.com

Phone: 0086 156 1977 8518(WhatsApp/Wechat)

If you want to know more details and prices of our products, please contact our sales manager, she will reply to you as soon as possible (usually within 24 hours), of course, you can also click the “REQUEST A QUOTE” button, or contact us directly by email us(Email:info@winnersmetals.com).

[Tungsten twisted wire heater: the core advantage in the field of PVD coating]

Tungsten twisted wire heater is an essential tool in the field of PVD vacuum coating, especially in the thermal evaporation process. With our professional manufacturing capabilities and comprehensive services, this product has won wide recognition in the market.

The material selection of our tungsten twisted wire heater is mainly tungsten, which has excellent high temperature stability and corrosion resistance and is suitable for various complex environments. Its precision manufacturing process ensures the reliability and durability of the heater, allowing it to operate continuously for a long time.

In addition, our tungsten twisted wire heaters are designed with the stability of heat distribution in mind, making the thermal evaporation process more uniform and efficient. At the same time, our professional service team will provide you with all-round support from equipment installation to daily maintenance, ensuring that your production process is worry-free.

When you choose our tungsten twisted wire heater, you will get efficient and stable equipment as well as professional and satisfactory service. Let our tungsten twisted wire heaters take full advantage of your PVD vacuum coating process and help you achieve greater success in the competition!