Tungsten & Molybdenum Parts for Ion Implantation

Tungsten & Molybdenum Parts for Ion Implantation

We provide high-precision ion-implanted tungsten and molybdenum spare parts. Our products have fine particle size, relative density greater than 99%, higher high-temperature mechanical properties than ordinary tungsten-molybdenum materials, and significantly longer service life.

These ion implantation components include:

• Electron emission cathode shielding cylinder.

• launch board.

• Center pole.

• Interrupter filament plate, etc.

Ion Implantation Parts Information

|

Products Name |

Ion Implantation Parts |

|

Material |

Pure Tungsten(W) / Pure Molybdenum(Mo) |

|

Purity |

99.95% |

|

Density |

W: 19.3g/cm³ / Mo: 10.2g/cm³ |

|

Melting Point |

W: 3410℃ / Mo: 2620℃ |

|

Boiling Point |

W: 5660℃ / Mo: 5560℃ |

|

Note: Processing according to drawings |

|

Ion Implantation

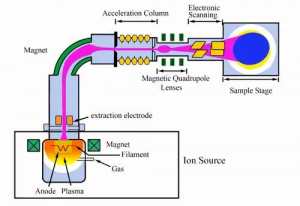

Ion implantation is an important process in semiconductor production. Implanter systems introduce foreign atoms into the wafer to change material properties, such as electrical conductivity or crystal structure. The ion beam path is the center of the implanter system. There, ions are created, concentrated, and accelerated toward the wafer at extremely high velocities.

When the ion source is converted to plasma ions, operating temperatures above 2000°C are created. When the ion beam is ejected, it also produces a large amount of ion kinetic energy. Metal generally burns and melts rapidly. Therefore, noble metal with higher mass densities is required to maintain the direction of the ion beam ejection and increase the durability of the components. Tungsten and molybdenum are the ideal material.

Why Choose Tungsten & Molybdenum Materials for Ion Implantation Components

• Good corrosion resistance • High material strength • Good thermal conductivity

They ensure that the ions are efficiently generated and precisely focused on the wafer in the beam path and free of any impurities.

Our Advantages

• High-quality raw materials

• Advanced production technology

• Precision CNC machining

• Strict quality control

• Shorter delivery time

We optimize based on the original production process of tungsten and molybdenum materials. Through grain refinement, alloying treatment, vacuum sintering and hot isostatic pressing sintering densification, secondary grain refinement and controlled rolling technology, the high-temperature resistance, creep resistance and service life of tungsten and molybdenum materials are significantly improved.

Semiconductor Ion Implantation Technology

Ion implantation is a commonly used process for doping and modifying semiconductor materials. The application of ion implantation technology has greatly promoted the development of semiconductor devices and the integrated circuit industry. Thus making the production of integrated circuits enter the era of large-scale and ultra-large-scale (ULSI).

Contact Us

Amanda│Sales Manager

E-mail: amanda@winnersmetals.com

Phone: +86 156 1977 8518(WhatsApp/Wechat)

If you want to know more details and prices of our products, please contact our sales manager, she will reply you as soon as possible (usually no more than 24h), thank you.