Spiral tungsten twisted wire factory OEM custom sales

Spiral tungsten twisted wire factory OEM custom sales,

Evaporating tungsten filament,

Tungsten (W) Evaporation Coils, Tungsten Heaters

The tungsten filament heater has the advantages of an extremely high melting point, excellent corrosion resistance and excellent material purity. It has high resistivity and low vapor pressure and is very suitable as an evaporation source. It is suitable for the evaporation of low melting point materials such as aluminum, indium, and tin.

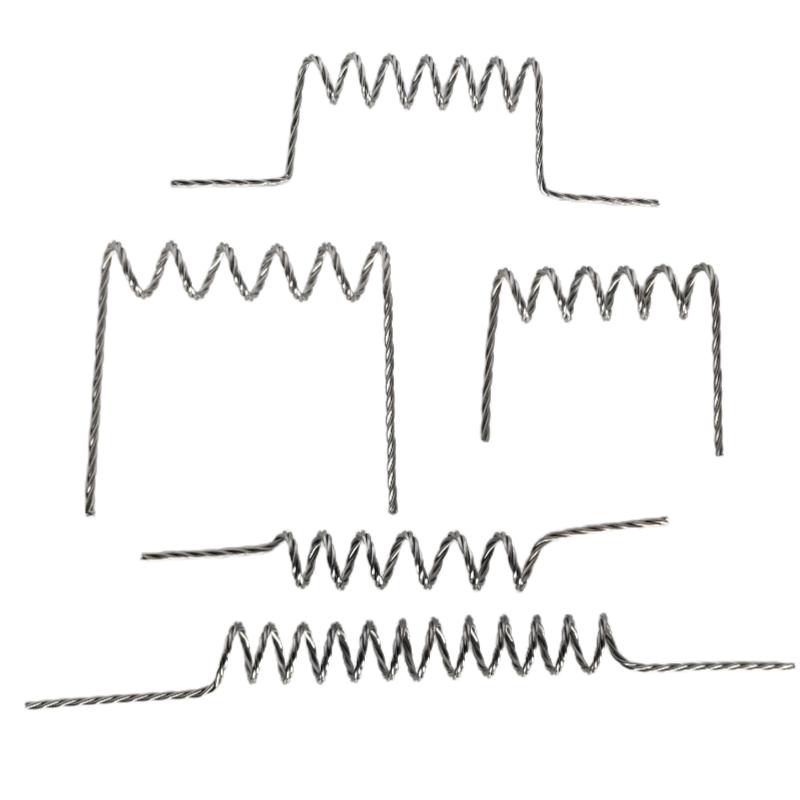

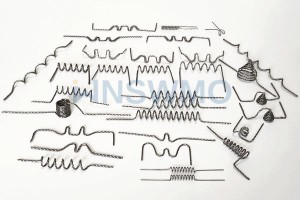

Tungsten evaporating coils are made of single-strand or multi-strand tungsten wire, which can be bent into various shapes according to installation or evaporation needs. We provide customers with various tungsten-stranded wire solutions, welcome to consult.

Tungsten Coil Information

| Product Name | Tungsten Coil Heater/Evaporation Coil |

| Purity | W≥99.95% |

| Density | 19.3g/cm³ |

| Melting Point | 3410°C |

| Strands | φ0.76X3, φ0.81X3, φ1.0X3, φ1.0X2, Can be customized. |

| MOQ | 3Kg |

| Application | Thermal Evaporation Coating |

Our Advantages

Our thermal filament tungsten heater has low energy consumption, long life and good evaporation effect, and is suitable for all kinds of vacuum evaporation machines.

Classification of Tungsten Filament Heaters

• Coil Heaters

• Basket Heaters

• Spiral Heaters

• Point and Loop Heaters

We can provide various forms of Tungsten Thermal Filament Sources, you can learn about these products through our catalog, welcome to consult us.

| Shape | Straight, U Shape, Can be customized |

| Number of Strands | 1, 2, 3, 4 |

| Coils | 4, 6, 8, 10 |

| Diameter of Wires(mm) | 0.76, 0.81, 1 |

| Length of Coils | L1 |

| Length | L2 |

| ID of Coils | D |

| Note: other specifications and filament shapes can be customized. | |

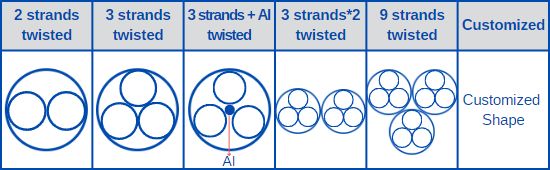

Stranded wire specification: φ0.76X3, φ0.81X3, φ1.0X3, φ1.0X2, φ0.81X4, φ0.81X3+Al, Can be customized.

We provide various tungsten wire stranding solutions to our customers.You can customize the required specifications and styles.

We provide evaporation sources and evaporation materials for PVD coating & Optical coating, these products include:

| Electron Beam Crucible Liners | Tungsten Coil Heater | Tungsten Cathode Filament |

| Thermal Evaporation Crucible | Evaporation Material | Evaporation Boat |

Don’t have the product you need? Please contact us, we will solve it for you.

Payment & Shipping

→PaymentSupport T/T, PayPal, Alipay, WeChat Pay, etc. Please negotiate with us for other payment methods.

→ShippingSupport FedEx, DHL, UPS, sea freight, and air freight, you can customize your transportation plan, and we will also provide cheap transportation methods for your reference.

Do you want to know more about our products?

Contact Me

Amanda│Sales Manager

E-mail: amanda@winnersmetals.com

Phone: 0086 156 1977 8518(WhatsApp/Wechat)

If you want to know more details and prices of our products, please contact our sales manager, she will reply to you as soon as possible (usually within 24 hours), of course, you can also click the “REQUEST A QUOTE” button, or contact us directly by email us(Email:info@winnersmetals.com).

Tungsten twisted wire, as a high-performance coating material, shows excellent performance in the vacuum thermal evaporation coating process. Its unique physical and chemical properties make it widely used in many specific fields such as optics, electronics and decoration.

In the field of optics, the high-temperature stability of tungsten twisted wire enables it to maintain stable optical performance in high-temperature environments, thereby improving the long-term performance of optical devices. In the electronic field, the thermal conductivity and corrosion resistance of tungsten twisted wire enable it to effectively conduct heat and improve the heat dissipation efficiency of electronic equipment. At the same time, its corrosion resistance also ensures the stable operation of electronic equipment. In the field of decoration, the high-temperature stability of tungsten strands enables it to form beautiful and durable decorative coatings during high-temperature evaporation, adding unique texture to various decorations.

Its stable physical and chemical properties and wide range of applications make tungsten stranded wire a star material in the coating process. Whether in scientific research, production or life, tungsten twisted wire will play a more important role in the future coating process field.