Short Lead Time for Flat Metal Diaphragm - Metal rotary target – WINNERS

Short Lead Time for Flat Metal Diaphragm - Metal rotary target – WINNERS Detail:

Product Description

An orthogonal magnetic field and electric field are added between the sputtered target (cathode) and the anode, and the required inert gas

(usually Ar gas)is filled in the high vacuum chamber.Under the action of the electric field, the Ar gas is ionized into positive ions And electrons,

a certain negative high pressure is applied to the target , the electrons emitted from the target are affected by the magnetic field and the

ionization probability of the working gas increases , forming a high-density plasma near the cathode , and Ar ions are under the action of

Lorentz force . Accelerate to fly to the target surface , bombard the target surface at a high speed, so that the sputtered atoms on the target

follow the momentum conversion principle and fly away from the target surface to the substrate to deposit a film with high kinetic energy.

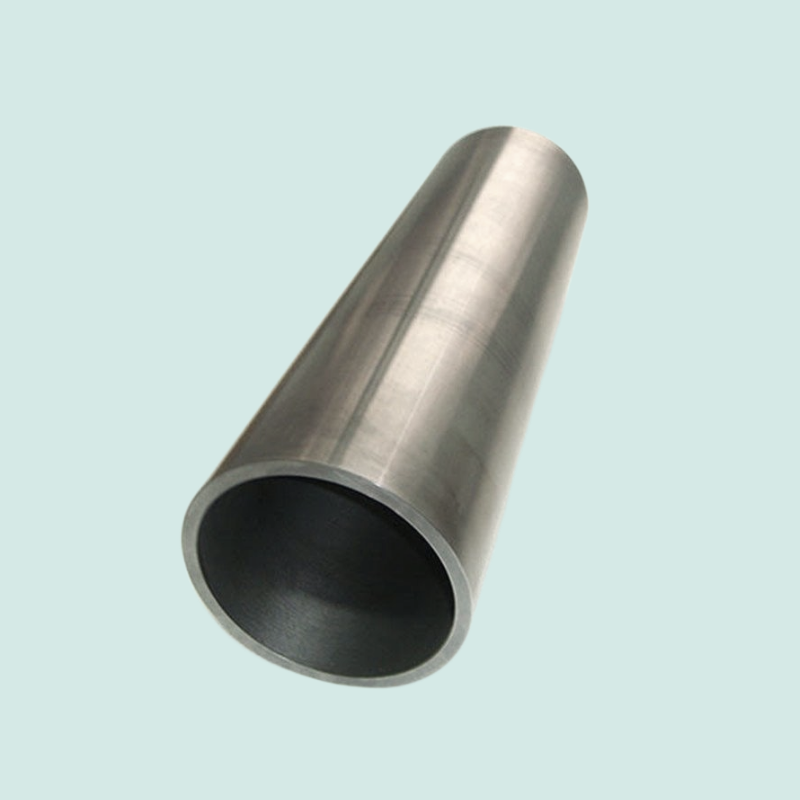

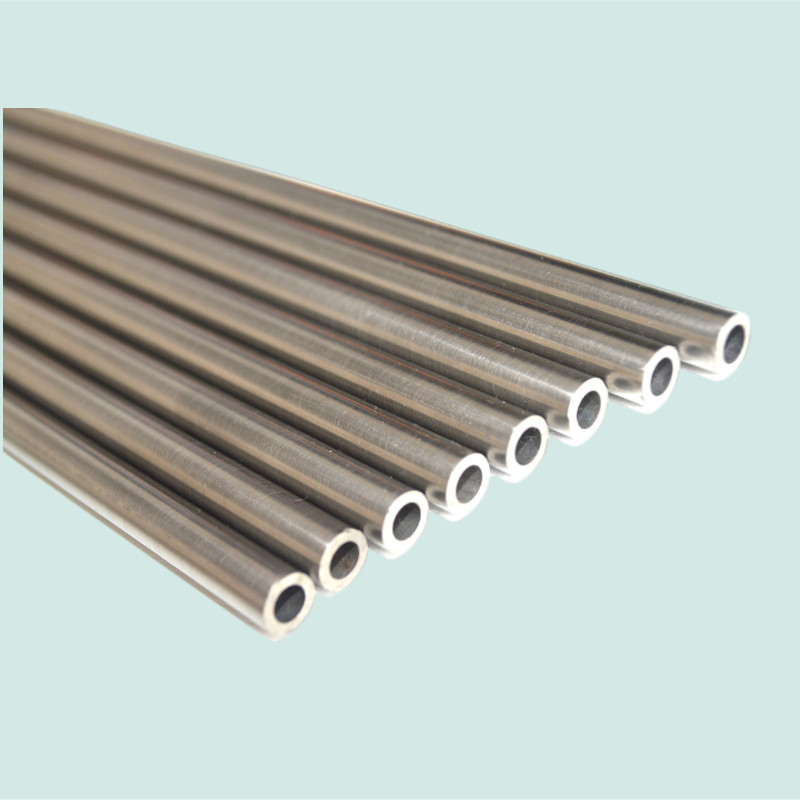

In order to further improve the utilization rate of the target material, a rotating cathode with higher use efficiency is designed, and a tubular

target material is used for sputtering coating. The improvement of sputtering equipment requires the target to be changed from a flat shape

to a tubular shape , and the utilization rate of the tubular rotating target can be as high as 70% , which largely solves the problem of low

utilization of the flat target.

Product Parameters

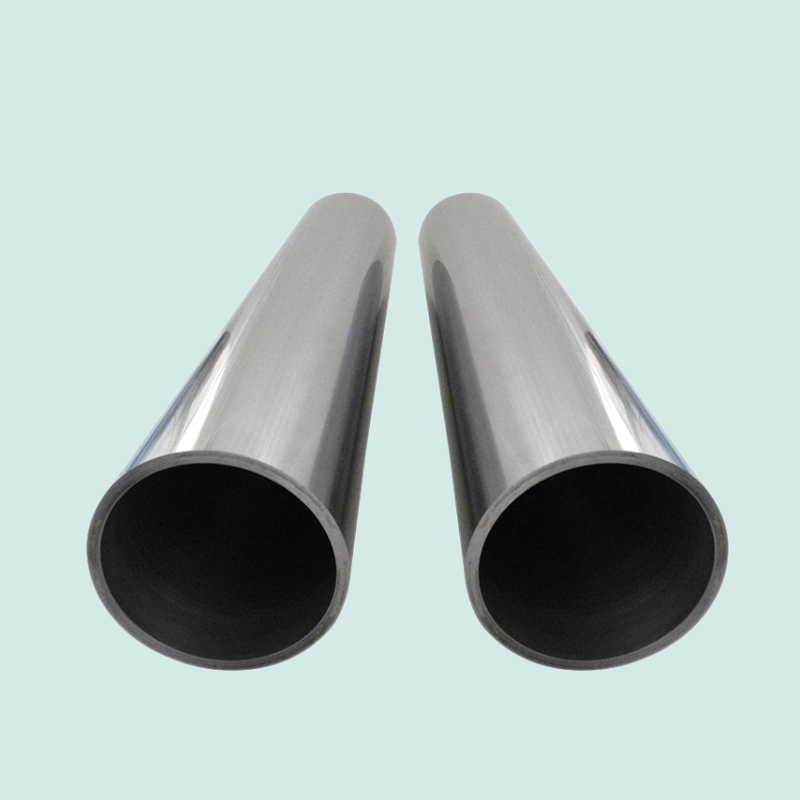

| Products name | Metal rotary target |

| Material | W, Mo, Ta, Ni, Ti, Zr, Cr, TiAl |

| Hot sale size | ID-133/ OD-157x 3191mm ID-133/OD-157 X 3855mm ID-160/OD-180x1800mm Can also be processed according to the specific requirements of customers |

| MOQ | 3 pieces |

| Package | Ply wooden case |

Note: We mainly produce various metal targets, please consult us for details.

Application

Sputtering coating is a new type of physical vapor coating method. Compared with evaporation coating method, it has obvious advantages in many aspects. Metal sputtering targets have been used in many fields. The main application of rotating target.

● Solar cells

● Architectural glass

● Auto glass

● Semiconductor

● Flat-screen TV, etc

Order Information

Inquiries and orders should include the following information ● Target specification ID*OD*L (mm). ● Quantity required. ● Please contact us for other special needs.

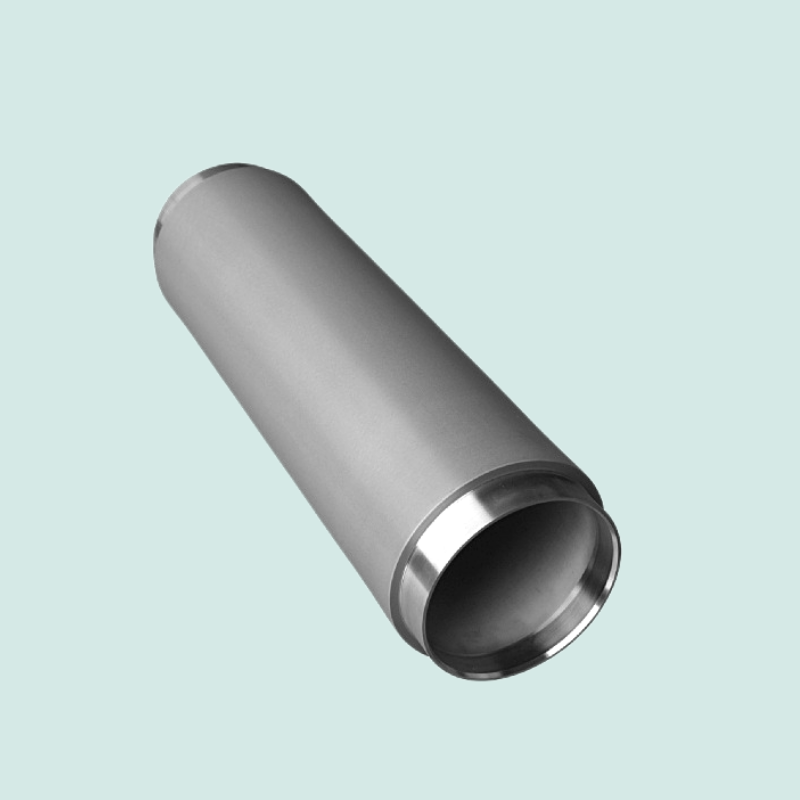

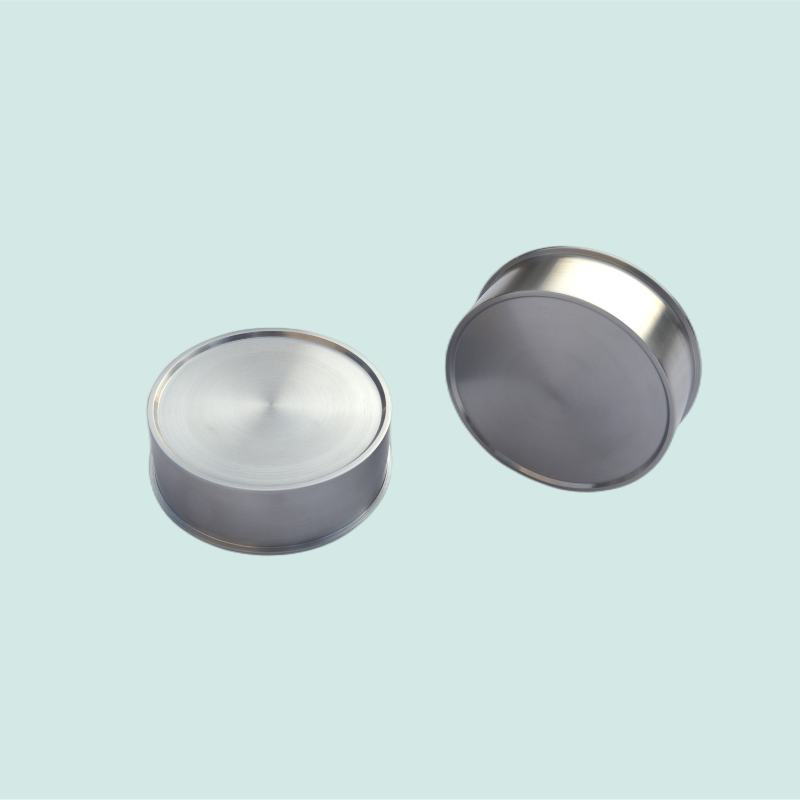

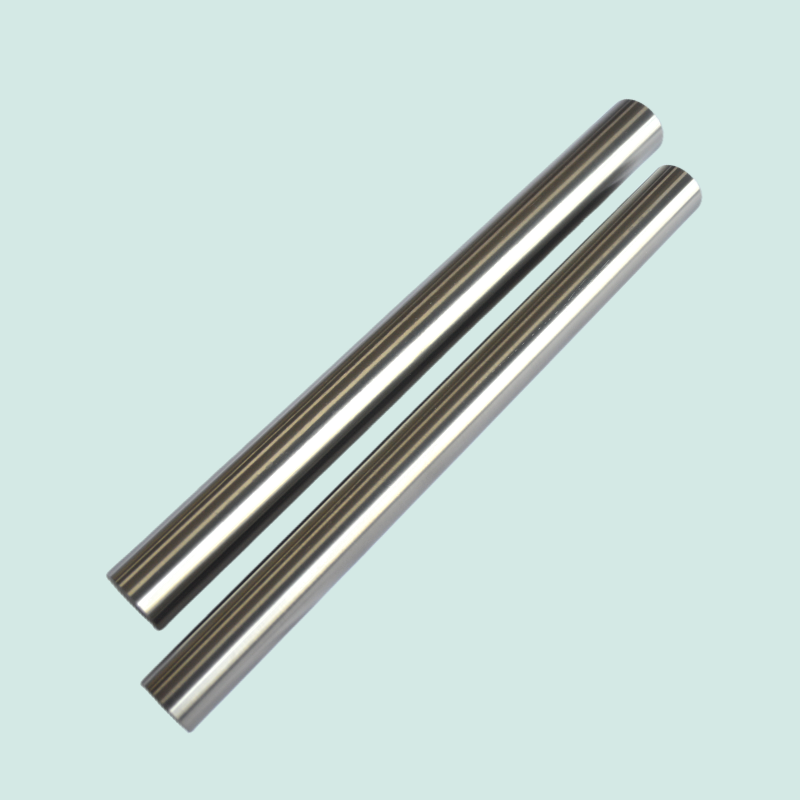

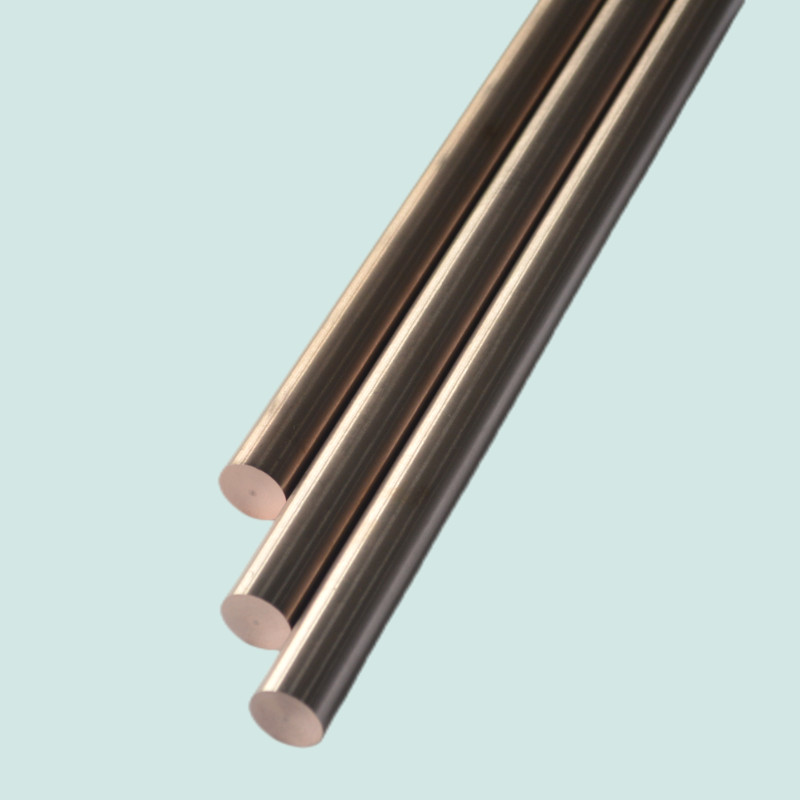

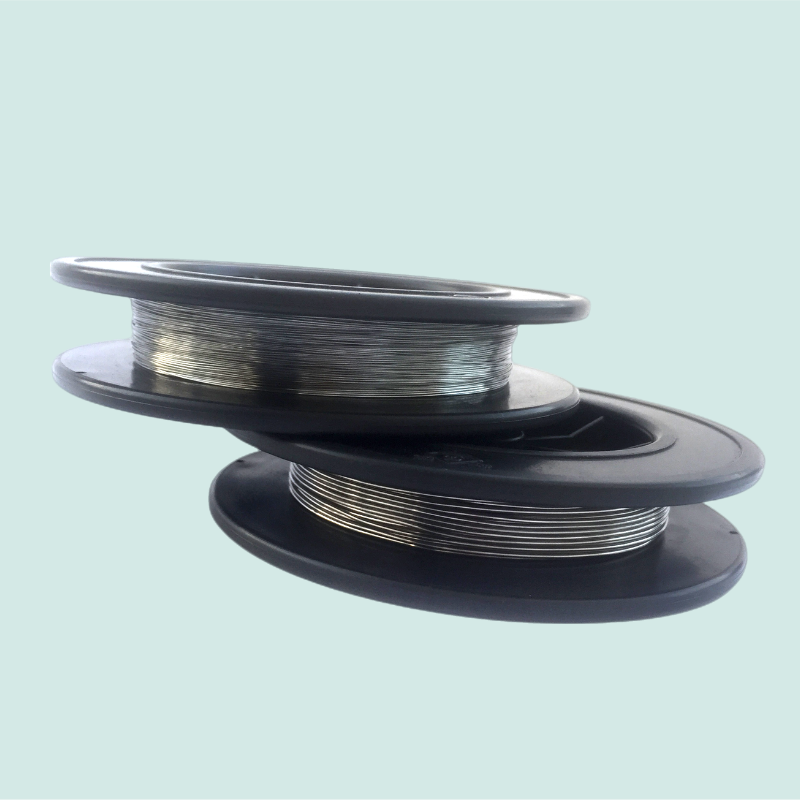

Product detail pictures:

Related Product Guide:

Our company since its inception, always regards product quality as enterprise life, continuously improve production technology, improve product quality and continuously strengthen enterprise total quality management, in strict accordance with the national standard ISO 9001:2000 for Short Lead Time for Flat Metal Diaphragm - Metal rotary target – WINNERS , The product will supply to all over the world, such as: Honduras, Norway, Uruguay, We only supply quality products and we believe this is the only way to keep business continue. We can supply custom service too such as Logo, custom size, or custom products etc that can according to customer's requirement.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!

Related Products

Write your message here and send it to us