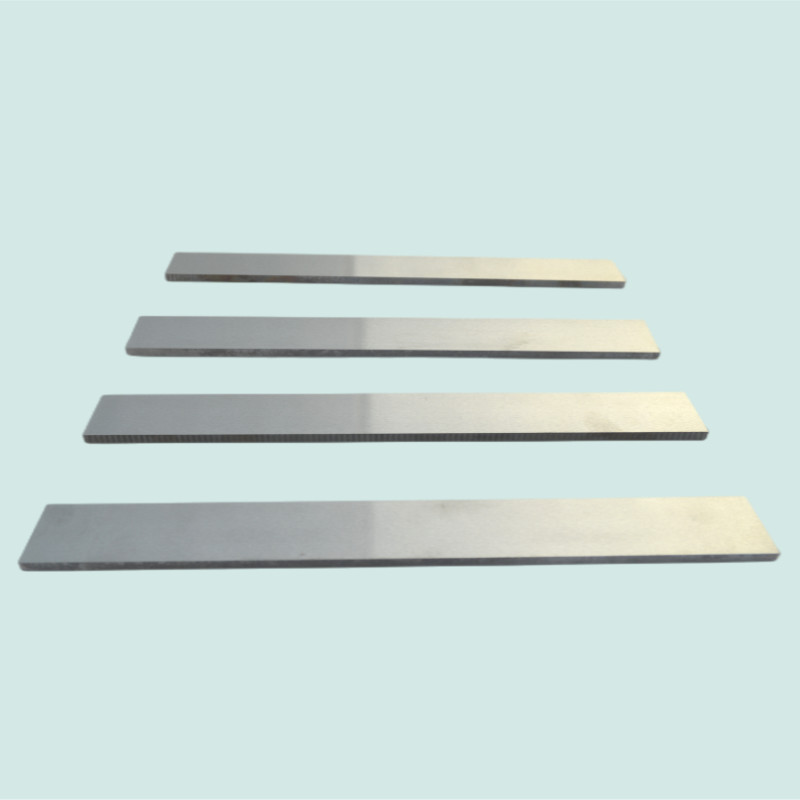

Quality Inspection for Tungsten Plate 5mm - Tungsten Wire Filaments Supplier – WINNERS

Quality Inspection for Tungsten Plate 5mm - Tungsten Wire Filaments Supplier – WINNERS Detail:

Product Description

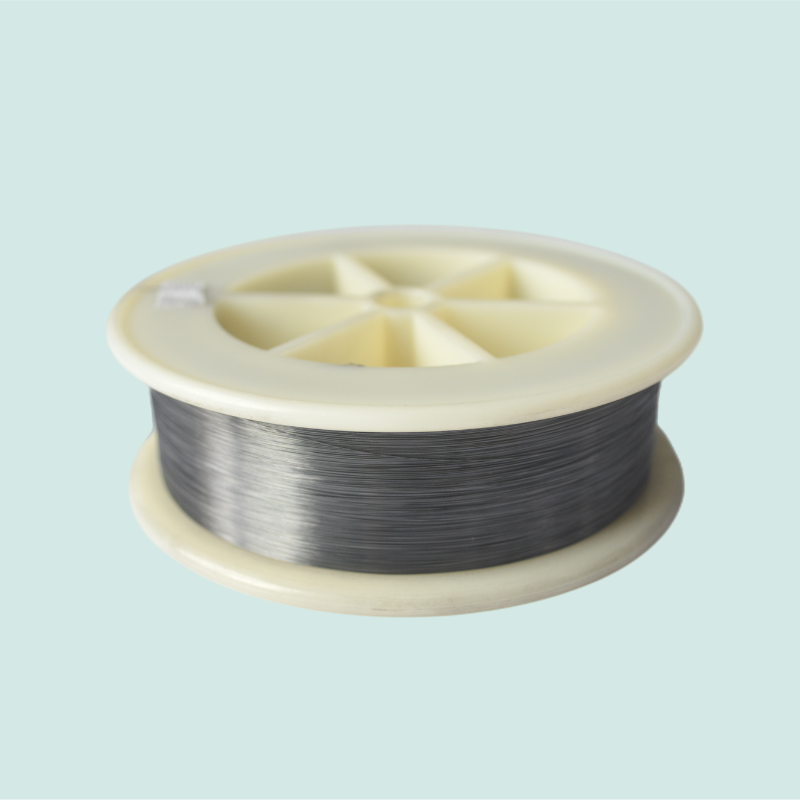

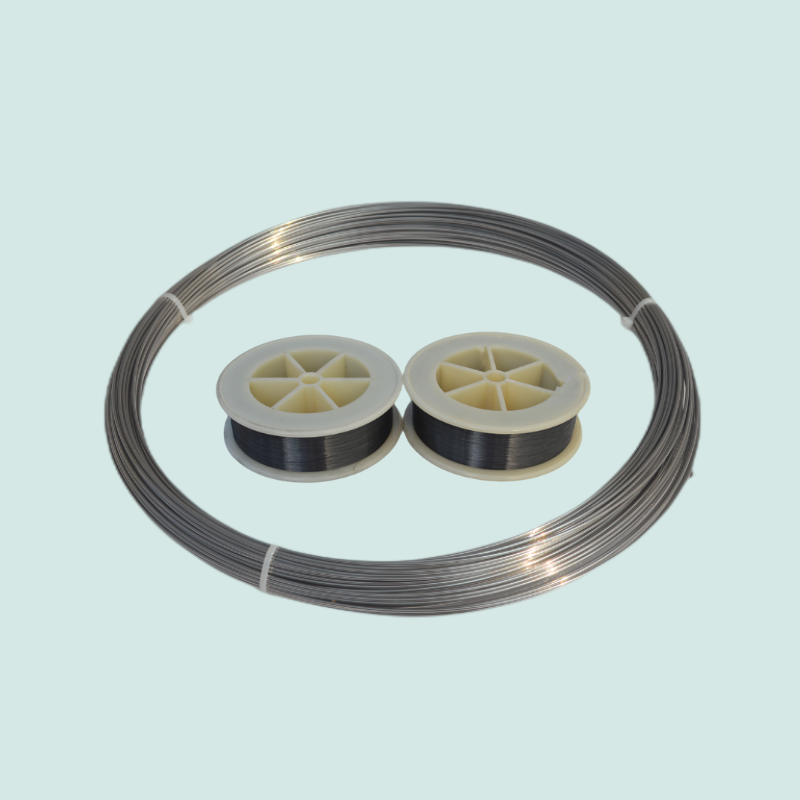

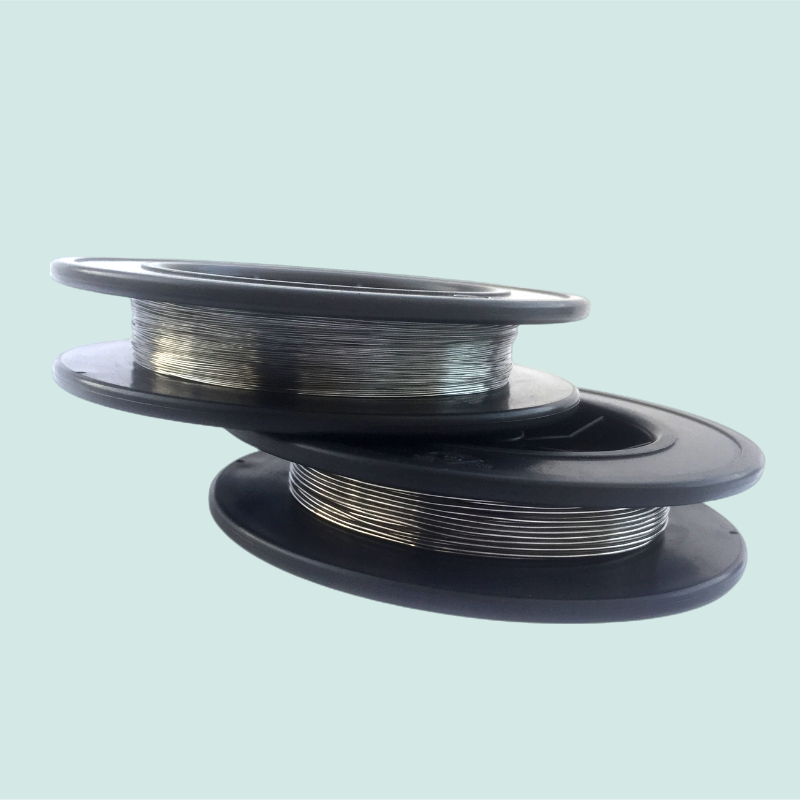

The resistivity of tungsten filament is 5.3*10^-8. Tungsten has a high melting point, high resistivity, good strength and low vapor pressure. It is the best material for making incandescent filaments among all pure metals. Tungsten wire is generally drawn by various drawing dies. The main purpose is to manufacture filament and high-speed cutting alloy steel, and also used in optical instruments, chemical instruments and so on.

Product Parameters

|

Products name |

Tungsten wire |

|

Grade |

W1, W2 |

|

Standard |

GB/T 4181-2017 |

|

Purity |

99.95%, 99.92% |

|

Density |

19.3g/cm³ |

|

Processing method |

Molding, sintering, forging, drawing |

|

Surface |

Black wire, bright wire |

Application

Application of tungsten and tungsten alloy wire.

Most of the tungsten filaments are used to make the filaments of various incandescent and tungsten halogen lamps and the electrodes of gas discharge lamps. People’s requirements for product quality and photoelectric parameter consistency of light bulbs are getting higher and higher, which requires us to improve the performance of tungsten wire by adding a small amount of other elements, so that it can meet the special requirements of certain fields.

|

Products name |

added ingredients |

Application field |

|

Pure tungsten wire |

/ |

Heating elements, evaporation coils, HID electrodes and coils, lead wires, hooks, side bars |

|

Doped tungsten wire |

0.2~0.4%SiO2 0.3~0.4%K2O |

Incandescent lamp single spiral filament, bracket, guide rod or lead wire |

|

0.02~0.05%Al2O3 0.2~0.4%SiO2 0.3~0.55%K2O |

Incandescent lamp double helix filament, tube cathode and heater, vapor deposition heater, fluorescent lamp filament |

|

|

Doped Thorium Tungsten Wire |

0.2~0.4%SiO2 |

Electron tube heating wire, argon arc welding electrode, connecting rod |

|

Thorium tungsten wire |

1.0% ThO2 |

Electrodes for Electron Tube Cathodes and High Intensity Gas Discharge Lamps, Emitting Tube Heat Wires, Hooks and Springs, Welding and Cutting Electrodes, etc. |

| Cerium tungsten wire | 1.5~3.0%CeO2 | Pulse tube heating wire, non-consumable welding electrode |

| Yttrium tungsten wire | 2.0~3.0%Y2O3 | Pulse tube heating wire, non-consumable welding electrode, HID electrode |

| Lanthanum tungsten wire | 1.0~2.0%La2O3 | Non-consumable welding electrodes |

| Tungsten and molybdenum wire | W-20Mo | Hooks, brackets, lead-out wires and other parts for lamps, heaters for electric vacuum devices |

| Tungsten rhenium wire | 1.0~26.0%Re | Aviation bulb filament, microwave device filament, electron beam tube filament, phenomenon tube filament |

Order Information

Inquiries and orders should include the following information.

● Surface: Back or bright wire.

● Diameter, weight or Length.

● Other special demand.

Product detail pictures:

Related Product Guide:

The key to our success is "Good Products Good quality, Reasonable Value and Efficient Service" for Quality Inspection for Tungsten Plate 5mm - Tungsten Wire Filaments Supplier – WINNERS , The product will supply to all over the world, such as: Victoria, Doha, Brasilia, Due to the changing trends in this field, we involve ourselves into products trade with dedicated efforts and managerial excellence. We maintain timely delivery schedules, innovative designs, quality and transparency for our customers. Our moto is to deliver quality products within stipulated time.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.