Physical vapor deposition (Physical Vapor Deposition, PVD) technology refers to the use of physical methods under vacuum conditions to vaporize the surface of a material source (solid or liquid) into gaseous atoms or molecules, or partially ionize into ions, and pass through low-pressure gas (or plasma). Process, a technology for depositing a thin film with a special function on the surface of a substrate, and physical vapor deposition is one of the main surface treatment technologies. PVD (physical vapor deposition) coating technology is mainly divided into three categories: vacuum evaporation coating, vacuum sputtering coating and vacuum ion coating.

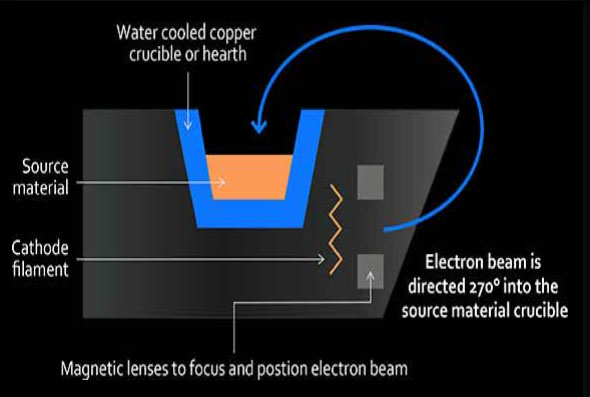

Our products are mainly used in thermal evaporation and sputtering coating. The products used in vapor deposition include tungsten strand wire, tungsten boats, molybdenum boats, and tantalum boats the products used in electron beam coating are cathode tungsten wire, copper crucible, tungsten crucible, and molybdenum processing parts The products used in sputtering coating include titanium targets, chromium targets, and titanium-aluminum targets.