Leading the pinnacle innovation of thin film technology---Tungsten Evaporation Coil product introduction

With the rapid development of science and technology, precision thin film deposition has become an indispensable key technology in many fields. Behind this technology, tungsten evaporation coils become an important tool for achieving high-quality thin films. Let’s take a closer look at this exciting technological innovation.

▶Product features

1. High purity tungsten material

Tungsten evaporation coils are made of highly pure tungsten material to ensure excellent quality of the material. High-purity tungsten is key to achieving uniform film deposition, providing reliable support for high-precision applications.

2. Excellent thermal conductivity

The coil design focuses on thermal conductivity to ensure even temperature distribution during the evaporation process. This excellent thermal conductivity helps ensure uniform deposition of the film on the substrate, improving production efficiency and product quality.

3. Precision craftsmanship

Tungsten evaporation coils are manufactured with precision processes to ensure a high degree of consistency in coil shape and size. This precision process ensures the controllability of the coil during the film deposition process, providing strong support for complex applications.

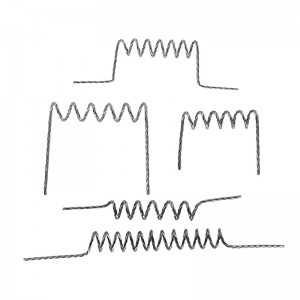

4. Diversified specifications

In order to meet the needs of different equipment and processes, tungsten evaporation coils are available in a variety of specifications and sizes. Customers can select the most suitable coil specifications based on their specific application requirements, enabling more flexible thin film deposition designs.

▶Application areas

☑ Optical coating

Used to make optical coatings to improve the performance and transmittance of optical devices.

☑ Electronic component manufacturing:

In the semiconductor industry, it supports the manufacturing of electronic components and improves device performance.

☑ Solar cell manufacturing

Provide high-quality thin films for solar cells and improve energy conversion efficiency.

Environmental protection and sustainable development

We are committed to environmentally friendly innovation. Our tungsten evaporation coils use environmentally friendly materials and processes and comply with the latest environmental standards. Through the concept of sustainable development, we help our customers achieve a more environmentally friendly production process.

Our service commitment

✔Excellent quality

Strict quality control ensures that each tungsten evaporation coil reaches high standards of performance.

✔Personalization

Provide services customized to customer needs to meet the requirements of specific applications.

✔Technical support

Our professional team will provide a full range of technical support and solutions to ensure customers can fully utilize the advantages of their products.

By choosing a tungsten evaporation coil, you not only choose excellent thin film deposition technology but also take a big step towards efficient and environmentally friendly production. Let us join hands to create a better technological future.

☏Contact us

Email: info@winnersmetals.com

Email: +86 156 1977 8518 (WhatsApp)

Post time: Jan-24-2024