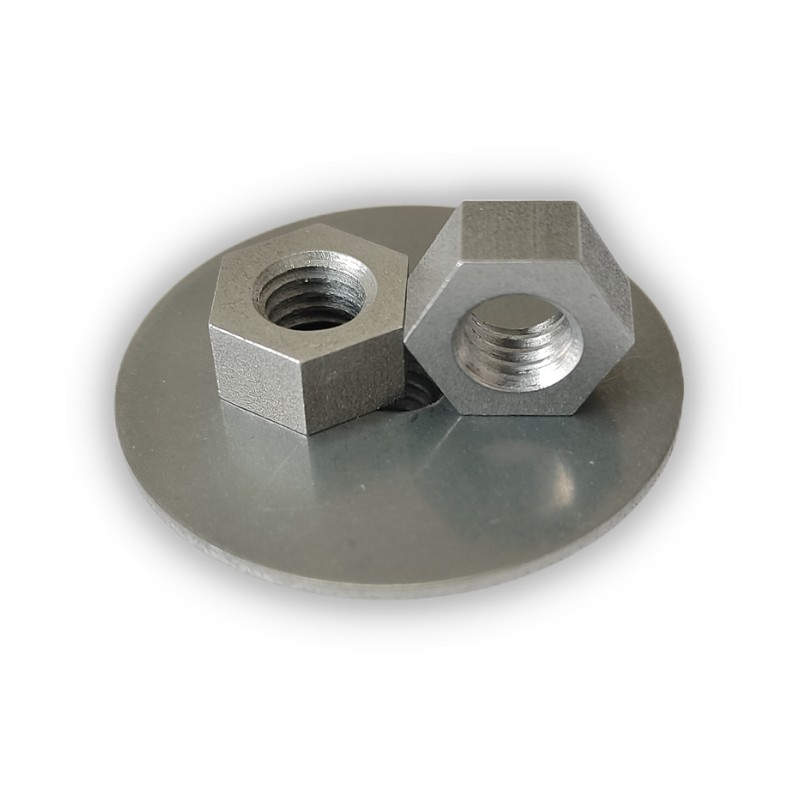

Molybdenum Screws and Nuts for Vacuum Furnaces

Molybdenum Screws/ Nuts/ Fasteners

Molybdenum screws and nuts have the characteristics of high melting point, high creep resistance, low thermal expansion and corrosion resistance, especially high-temperature resistance and low expansion, and still have good physical strength at 1700 degrees. Therefore, it widely uses in various high-temperature resistant industries.

We provide tungsten, molybdenum, tantalum high temperature resistant connecting elements, such as screws, nuts, washers, threaded posts, etc.

You can view our high temperature vacuum furnace tungsten molybdenum accessories products.

Where are molybdenum screws and nuts used?

• Bolts for glass furnace.

• Fasteners for single crystal furnace.

• Bolts and nuts for a sapphire crystal furnace.

• Shielding screws for the semiconductor and electronic industries.

• Molybdenum screw and Molybdenum nut for high temperature vacuum furnace or gas holding furnace.

Molybdenum Screws Information

| Products Name | Molybdenum Screws |

| Standard | GB, DIN, ISO, ASME/ANSI, JIS, EN |

| Material | Pure Mo, TZM, MoLa |

| Operating temperature | 1100~1700℃ |

| Density | 10.2g/cm³ |

| Surface | Machined, Polishing |

| Dimensions | M3~M30, can be customized |

| Head type | Slotted, T-shaped head, hexagonal head or as your drawing |

Head Types of Molybdenum Screws

The heads of molybdenum screws generally have straight grooves, T-heads, square heads, hexagonal heads, etc. The threads generally have M3-M30 or inch thread standards. We support customizing other sizes and types of molybdenum screws.

What are the advantages of molybdenum material?

• Excellent high-temperature resistance

• Excellent electrical conductivity

• Low coefficient of thermal expansion

• Good corrosion resistance

Do you want to know more about our products?

Contact Me

Amanda│Sales Manager

E-mail: amanda@winnersmetals.com

Phone: 0086 156 1977 8518(WhatsApp/Wechat)

If you want to know more details and prices of our products, please contact our sales manager, she will reply you as soon as possible (usually no more than 24h), thank you.