Molybdenum Heat Shield

Molybdenum Heat Shield

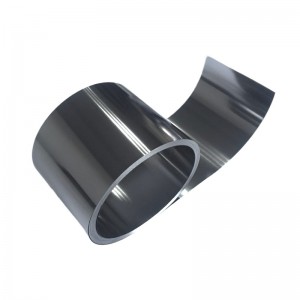

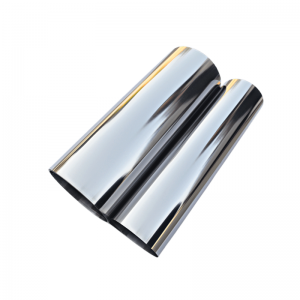

Heat shields are used in high-temperature vacuum furnaces, and their biggest function is to block and reflect the heat in the furnace. Therefore, heat shields with high purity, accurate size, smooth surface, convenient assembly, and reasonable design are very important.

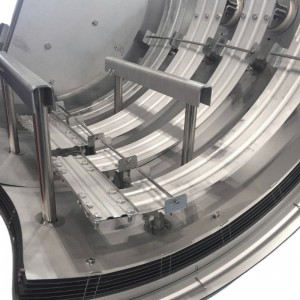

Molybdenum insulation boards are generally produced and processed with 0.5-1.2mm molybdenum sheets. Generally there are 4-6 layers. The inner layer of the furnace is made of high-temperature molybdenum TZM material with a thickness of 1.2mm. Use molybdenum strips as interlayers with a spacing of 7mm. Other molybdenum heat shields are made of 0.5-0.8mm MO1 material.

The heat shield is generally fastened with molybdenum bolts or riveted with molybdenum sheets, and we can also provide these accessories.

Heat Shield Design Points

| ●Thermal properties of materials

The maximum temperature of the selected metal material should be higher than the ambient working temperature, and the thermal deformation of the metal should be small. When the temperature is higher than 900°C, tungsten, molybdenum, and tantalum sheets are generally used. Stainless steel sheets are generally used below 900 °C. ●Material blackness The low blackness material is selected, the surface reflection effect is better, and the surface finish is higher. ●Material thickness The thickness of the insulation sheet should be as thin as possible. Molybdenum is generally 0.2 ~ 0.5mm. Stainless steel plate is generally 0.5 ~ 1mm. ●Material price Under the condition of satisfying the working temperature, the material cost should be considered and the cheaper material should be selected. ●Determination of the number of heat shield layers As the number of layers increases, the heat loss decreases, the cost increases, the structure is complicated, and the vacuum degree is more difficult to meet the work requirements. Increasing to three layers increases by about 8%. The number of layers is not the more the better, it should be considered comprehensively. The working temperature is 1000℃, and up to six layers can be used. ●Heat shield spacing Spacing should be minimized. The thermal effect of increasing the distance is not large. If the spacing is too small, the two insulation boards will be connected due to thermal deformation. Reduce the spacing, generally around 10mm. ●Connection between layers Each layer of the heat shield should be connected, and the contact area of the connection should not be too large, which will reduce thermal efficiency. Connect each layer using sleeves and washers. ●Maintenance of heat shield The design of the heat shield should be easy to disassemble, and at the same time, the thermal expansion and contraction properties of the material should also be considered. ●The distance between the first layer screen and the radiation surface Generally 50~100mm ●The distance from the outermost screen to the circulating water wall Generally 100~150mm |

We specialize in the production of various high-temperature resistant accessories for vacuum furnaces: heating elements, heat shields, material pans, material racks, material boats, material boxes, and furnace standard parts. The materials provided are tungsten(W), molybdenum(Mo), tantalum(Ta), etc.

Do you want to know more about our products?

Contact Us

Amanda│Sales Manager

E-mail: amanda@winnersmetals.com

Phone: +86 156 1977 8518(WhatsApp/Wechat)

If you want more details and prices of our products, please contact our sales manager, she will reply as soon as possible (usually no more than 24h), thank you.