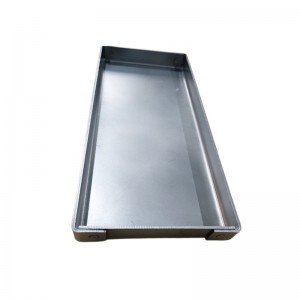

Molybdenum Boats for Thermal Evaporation

Molybdenum (Mo) Boats

Molybdenum boats are important components used in physical vapor deposition (PVD) processes, especially thermal evaporation techniques. These boats serve as crucibles or vessels to contain and evaporate solid source materials, allowing thin films to be deposited onto substrates.

Molybdenum boats used in thermal evaporation processes can be classified based on several factors, including their shape, size, and specific application requirements. The following are the classifications of molybdenum boats:

• According to different shapes, molybdenum boats are round, rectangular, square and trapezoidal;

• According to different processing methods, molybdenum boats can be divided into stamping boats, folding boats, welding boats, and riveting boats;

• According to different materials, it can be divided into pure molybdenum boats, molybdenum-lanthanum boats, molybdenum-zirconium-titanium boats, molybdenum-rhenium boats, tungsten-molybdenum boats, etc.

Molybdenum (Mo) Boats

| Products Name | Molybdenum Boats |

| Material | Mo1, MoLa |

| Density | 10.2g/cm³ |

| Purity | ≥99.95% |

| Technology | Riveting, Stamping, etc. |

| Application | Vacuum Metallization |

Advantages of Molybdenum Boat

The molybdenum boat is an important component of the thermal evaporation process in vacuum deposition applications. Some of its key advantages include:

• High-temperature stability

• Uniform heating and vaporization

• Chemically inert

• Design versatility

• Compatibility with vacuum environments

• Durability and longevity

• Wide range of applications

Application

Molybdenum boats have a variety of applications in industries that use thermal evaporation processes for thin film deposition. Some common applications include semiconductor manufacturing, optics and photonics, surface modification and functional coatings, thin film research and development, materials science and engineering, solar cell and photovoltaic industry, decorative and functional coatings, etc.

Molybdenum Boat Shape Selection

| Flat groove molybdenum boat | Suitable for high wettability materials. |

| The v-shaped groove molybdenum boat | Suitable for materials with less wettability. |

| Oval grooved molybdenum boat | Suitable for materials in a molten state. |

| Spherical groove molybdenum boat | Suitable for expensive materials such as gold and silver. |

| Narrow slot molybdenum boat | This design prevents the vapor deposition material from sticking to the filament clip. |

Popular Size

|

Model |

Thickness (mm) |

Width(mm) |

Length(mm) |

|

#210 |

0.2 |

10 |

100 |

|

#215 |

0.2 |

15 |

100 |

|

#220 |

0.2 |

20 |

100 |

|

#310 |

0.3 |

10 |

100 |

|

#315 |

0.3 |

15 |

100 |

|

#320 |

0.3 |

20 |

100 |

|

#510 |

0.5 |

10 |

100 |

|

#515 |

0.5 |

15 |

100 |

|

Note: Special specifications and dimensions can be processed according to drawings or samples. |

|||

We provide evaporation sources and evaporation materials for PVD coating & Optical coating, these products include:

| Electron Beam Crucible Liners | Tungsten Coil Heater | Tungsten Cathode Filament |

| Thermal Evaporation Crucible | Evaporation Material | Evaporation Boat |

Don't have the product you need? Please contact us, we will solve it for you.

Do you want to know more about our products?

Contact Us

Amanda│Sales Manager

E-mail: amanda@winnersmetals.com

Phone: +86 156 1977 8518(WhatsApp/Wechat)

If you want to know more details and prices of our products, please contact our sales manager, she will reply you as soon as possible (usually no more than 24h), thank you.