Molybdenum Crucibles for E-Beam Sources

Molybdenum E-Beam Crucibles

Molybdenum electron beam crucibles are used in electron beam evaporation processes. Molybdenum crucible liners are protective layers or inserts made of molybdenum metal that are placed inside the crucible to enhance its performance and durability in high-temperature applications. Choosing the appropriate crucible liner size can maximize film deposition efficiency and reduce production costs.

Molybdenum electron beam crucibles are typically made from high-purity molybdenum metal. Molybdenum has a high melting point (2,620 ℃), excellent thermal conductivity, and resistance to thermal shock and chemical attack.

We offer molybdenum electron beam crucible liners in 4cc, 7cc, 15cc, 25cc, 30cc, 40cc, 100cc and more specifications.

Our molybdenum crucibles are processed from high-purity forged molybdenum rods, which feature high precision, high purity, no pollution, long life, high-temperature resistance, and excellent creep resistance and corrosion resistance.

Molybdenum Crucible Information

| Product Name | Molybdenum (Mo) Crucibles |

| Purity | 99.95% |

| Density | 10.2g/cm³ |

| Melting Point | 2620℃ |

| Working Temperature | 1100℃-1800℃ |

| Production Process | Machined-Polishing |

| Application | E-Beam Evaporation, Lab use |

| Type | 4cc, 7cc, 15cc, 25cc, 30cc, 40cc, 100cc, Can be customized |

| MOQ | 2 pieces |

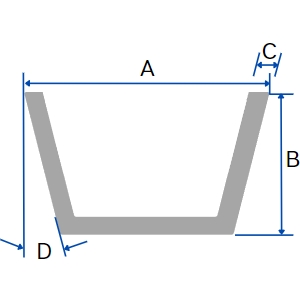

Molybdenum Crucible Dimensions

Tips:

1. The drawing is for standard crucibles, which can be produced according to the corresponding specifications.

2. Other types of crucibles can be customized.

3. For customers who do not have drawings, we can make drawings for you free of charge and confirm the detailed dimensions.

| Pocket Volume | Top Diameter(A) | Height(B) | Wall Thickness(C) | Angle(D) |

| 4cc | 0.885 in (22.48mm) | 0.595 in (15.11mm) | 0.093 in (2.36mm) | 15° |

| 7cc | 1.167 in (29.64mm) | 0.563 in (14.30mm) | 0.093 in (2.36mm) | 15° |

| 12cc | 1.334 in (33.88mm) | 0.768 in (19.51mm) | 0.093 in (2.36mm) | 15° |

| 15cc | 1.48 in (37.59mm) | 0.67 in (17.02mm) | 0.125 in (3.18mm) | 15° |

| 20cc | 1.673 in (42.49mm) | 0.768 in (19.51mm) | 0.093 in (2.36mm) | 15° |

| 25cc (4 Pocket) | 1.85 in (46.99mm) | 0.68 in (17.27mm) | 0.125 in (3.18mm) | 15° |

| 25cc (6 Pocket) | 1.633 in (41.48mm) | 0.94 in (23.88mm) | 0.125 in (3.18mm) | 15° |

| 30cc (with web) | 1.92 in (48.77mm) | 0.81 in (20.57mm) | 0.093 in (2.36mm) | 15° |

| 30cc (without web) | 1.775 in (45.09mm) | 0.94 in (23.88mm) | 0.125 in (3.18mm) | 15° |

| 40cc | 2.03 in (51.56mm) | 1.02 in (25.91mm) | 0.125 in (3.18mm) | 15° |

| Allows customization of more sizes or production according to drawings to meet your needs. | ||||

Application

Molybdenum electron beam crucibles are widely used in thin film deposition applications in various industries:

• Semiconductor Manufacturing.

• Optical Coatings.

• Solar cell production.

• Research and development.

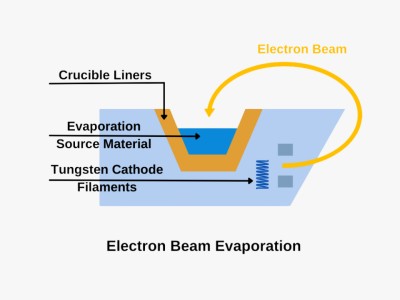

About Electron Beam Evaporation Coating

The electron beam evaporation method is a kind of vacuum evaporation coating, which uses electron beams to directly heat the evaporation material under vacuum conditions, vaporize the evaporation material and transport it to the substrate, and condense on the substrate to form a thin film.

Electron beam evaporation can evaporate high melting point materials, which have higher thermal efficiency, higher beam current density and faster evaporation than general resistance heating evaporation. The prepared thin film has high purity and good quality, can control the thickness more accurately, and can be widely used in the preparation of various optical material thin films such as high-purity thin films and conductive glass.

Why Choose Us?

We provide you with higher quality pure molybdenum crucibles, our main advantages are as follows:

☑ Processed with high-purity molybdenum rods to ensure purity.

☑ Professional manufacturing, higher product precision, and bright surface.

☑ Short delivery time and favorable price.

☑ Small minimum order quantity, support customization.

With more than ten years of industry experience, we can produce molybdenum crucibles with very high density and purity, accurate dimensions, smooth surface, high-temperature resistance, and corrosion resistance.

Our crucibles are used by many customers around the world with great success. Whether it is a small crucible for laboratory use (10mm diameter) or a large crucible for industrial use (300mm diameter), we can produce it.

We provide evaporation sources and evaporation materials for PVD coating & Optical coating, these products include:

| Electron Beam Crucible Liners | Tungsten Coil Heater | Tungsten Cathode Filament |

| Thermal Evaporation Crucible | Evaporation Material | Evaporation Boat |

Don't have the product you need? Please contact us, we will solve it for you.

Do you want to know more about our products?

Contact Us

Amanda│Sales Manager

E-mail: amanda@winnersmetals.com

Phone: +86 156 1977 8518(WhatsApp/Wechat)

If you want to know more details and prices of our products, please contact our sales manager, she will reply you as soon as possible (usually no more than 24h), thank you.