Molybdenum crucible for electron beam evaporation

Product Description

Molybdenum Crucible for Evaporation Coating

The density of molybdenum is 10.2g/cm³, the melting point is 2610℃, and the boiling point is 5560℃. Molybdenum is a silver-white metal, hard and tough, with a high melting point, high thermal conductivity, and corrosion resistance.

The normal use temperature of pure molybdenum crucible is generally 1100℃~1700℃. When used in vacuum coating, it can effectively resist high temperature and prevent possible contamination of the coating during coating.

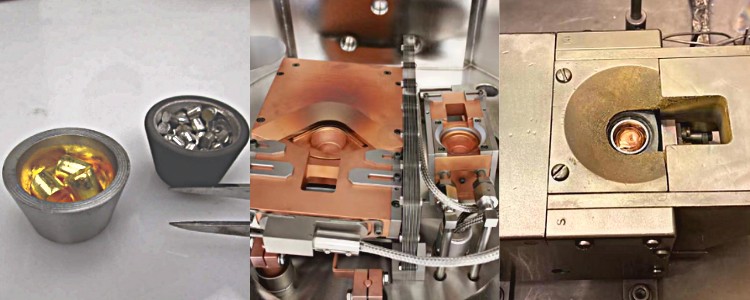

Molybdenum and tungsten forming crucibles have excellent properties, and these crucibles are ideal vessels for the melting and solidification of single crystals. Our molybdenum and tungsten crucibles are of high purity, high temperature resistance, excellent creep resistance, and corrosion resistance. Therefore, our molybdenum and tungsten crucibles are widely used in PVD coating, sapphire, rare earth smelting and other industries.

Product parameters

|

Products name |

Molybdenum crucibles |

|

Purity |

99.95% |

|

Density |

10.2g/cm3 |

|

MOQ |

2 piece |

|

Capacity |

3ml~50ml or as your demand |

|

Max working temperature |

1700℃ |

|

Production Process |

Machined-Polishing |

We can provide you with metal crucible materials:

Tungsten, Molybdenum, Tantalum, Copper (oxygen-free copper), and various specifications can be processed.

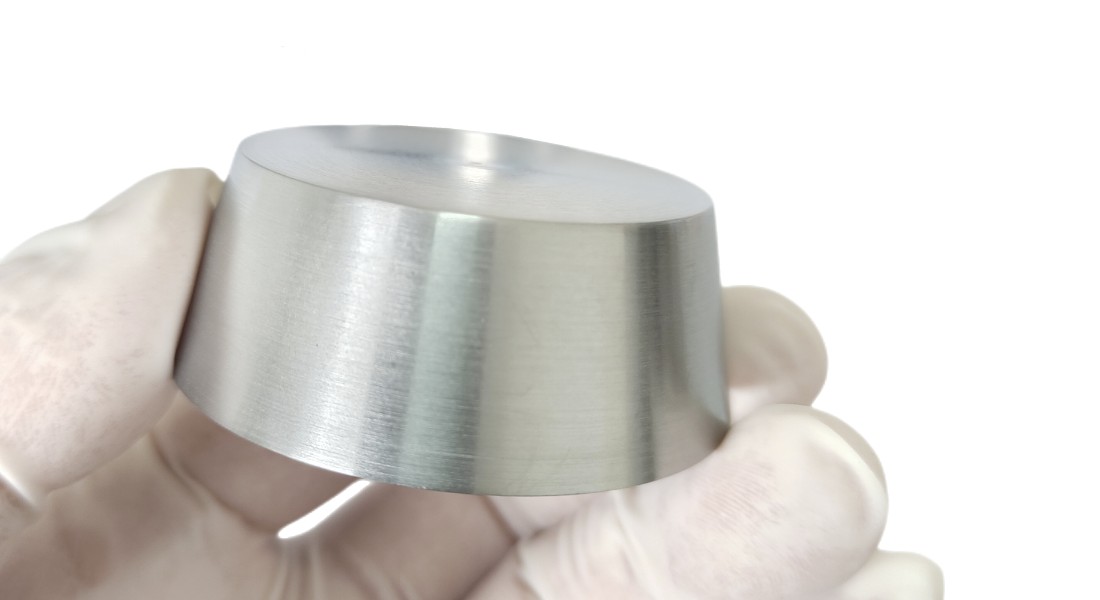

Products real shot

Product advantages

■ No pollution, long service life.

■ Ability to change materials quickly.

■ Improve evaporation rate, shorten cycle time and increase production.

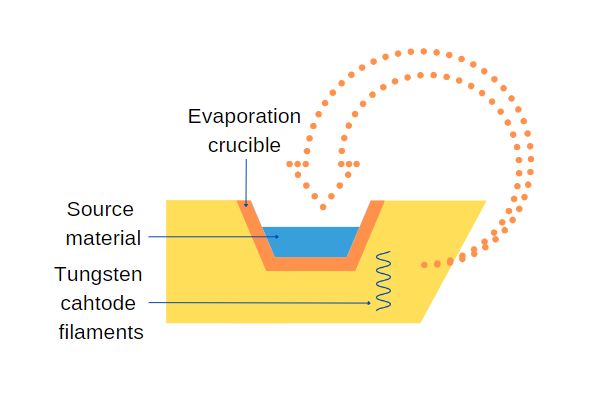

Application

■ Optical coating ■ Electron beam evaporation coating ■ For scientific research

Crucibles Selection Table

|

Evaporator |

Crucible materials |

||

|

|

W |

Mo |

Ta |

|

Aluminium |

|

√ |

√ |

|

Alumina Al2O3 |

|

√ |

√ |

|

Beryllium |

√ |

√ |

√ |

|

Gallium |

√ |

√ |

√ |

|

Gold |

|

√ |

√ |

|

Lead |

√ |

√ |

√ |

|

Iron |

√ |

√ |

√ |

|

Platinum |

√ |

√ |

√ |

|

Evaporator |

Crucible materials |

||

|

|

W |

Mo |

Ta |

|

Silicon |

√ |

√ |

|

|

Silver |

√ |

|

√ |

|

Titanium |

|

√ |

√ |

|

Magnesium |

√ |

√ |

√ |

|

Titanium Dioxide |

√ |

√ |

|

|

Zirconium |

|

√ |

√ |

|

Zirconium Oxide |

|

√ |

√ |

Our advantages

Selection of high-quality molybdenum powders to ensure purity

Professional production, accurate product size, bright surface

Reasonable technology, short delivery time and preferential price

Customized according to drawings, even 1 piece can be produced

With our more than ten years of experience, we can produce very high density and purity tungsten and molybdenum crucibles, which are dimensionally accurate, have smooth surfaces, and have excellent creep resistance.

Our Tungsten Molybdenum Crucibles have been favored by many customers all over the world who use our products and create great value. Whether you have a small crucible (diameter 10mm) for laboratory use or a large crucible (diameter 500mm) for industrial use, we can meet your need.

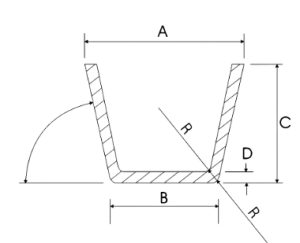

Order Information

Inquiries and orders should include the following information:

✔ Material(Tungsten, Molybdenum, Tantalum, Copper(Oxygen-free copper))

✔ Drawing of the crucibles, if there is no drawing, tell us the Outer diameter, wall thickness, angel and height

✔ Quantity

To learn more about our products, please click to view.

If you want to know more about the product, please contact us, our sales manager and engineer will reply you within 24h.

Contact Me

Amanda│Sales Manager

E-mail: amanda@winnersmetals.com

Phone: 0086 156 1977 8518(Whatsapp/Wechat)

About Us

We are an entity manufacturer in China, we independently produce and process raw materials of tungsten, molybdenum, tantalum, niobium and their processed parts.

The products mainly involve industries:

■Tungsten and molybdenum spare parts for high temperature furnaces (such as heating elements, connecting parts (screws, screw rods, nuts, pins, washers and bolts, etc.), heat shields, molybdenum material boxes, etc.).

■Machining crucibles and sintered crucibles of tungsten, molybdenum and tantalum (used in rare earth smelting, quartz glass, vacuum coating, crystal growth and other industries).

■Tungsten tubes, molybdenum tubes, tantalum tubes (for thermocouple protection tubes, high temperature instrument accessories, high temperature furnace refractory parts, etc.).

■Tungsten, molybdenum, tantalum, niobium raw materials (bars, plates, pipes, wires, etc.) and related processed products.

We adhere to the principle of "integrity management" and "high-quality products" as the core, and actively help customers to reduce costs reasonably. We are constantly pursuing "innovation", only to make better "products" with our hearts. Come with us to witness a better tomorrow.