Leading Manufacturer for Black Mo1 Molybdenum Wire - Molybdenum heat shield – WINNERS

Leading Manufacturer for Black Mo1 Molybdenum Wire - Molybdenum heat shield – WINNERS Detail:

Product Description

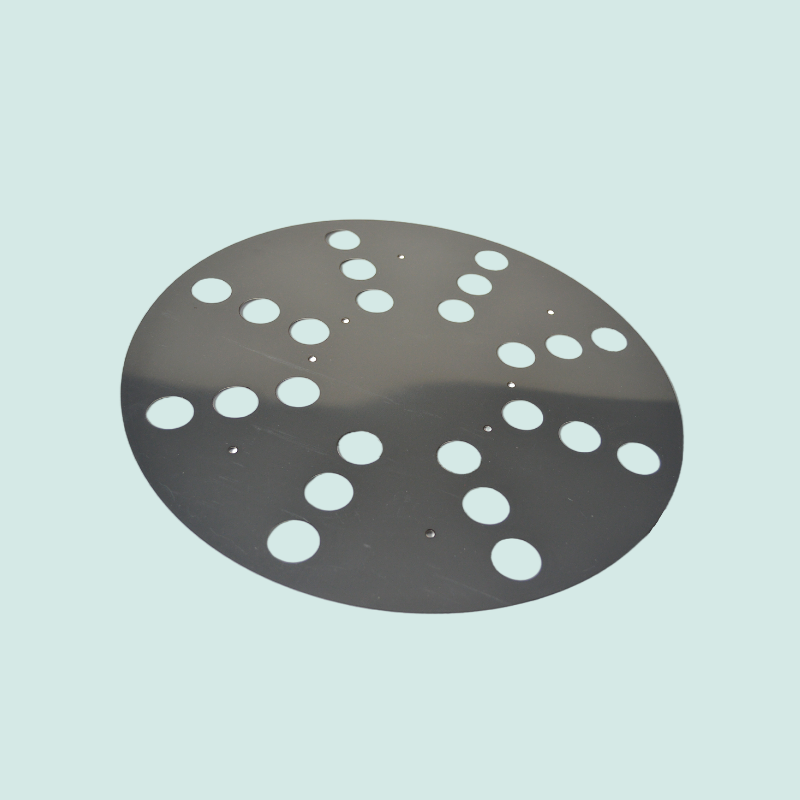

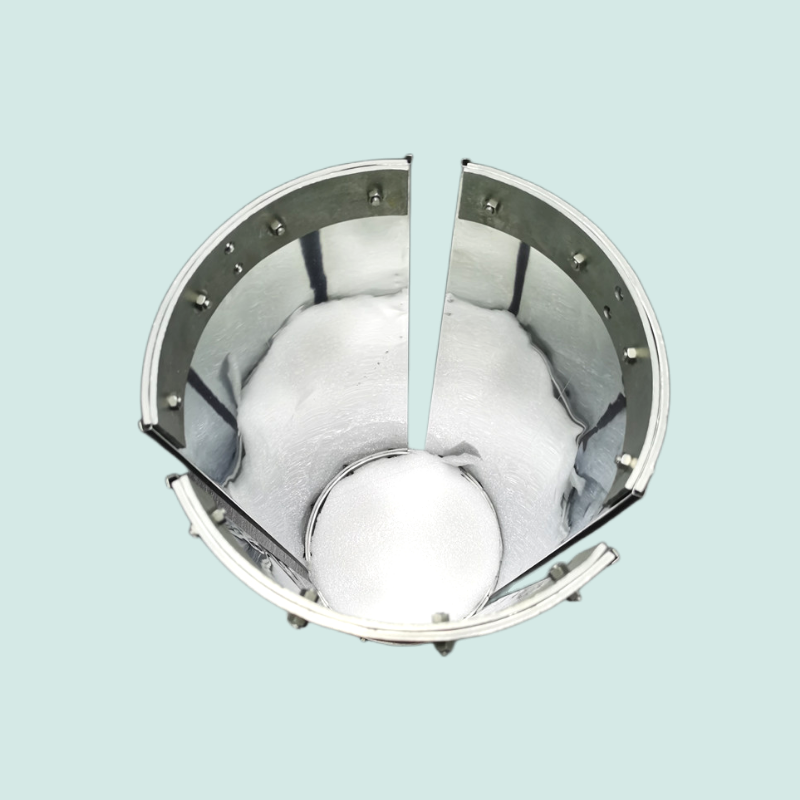

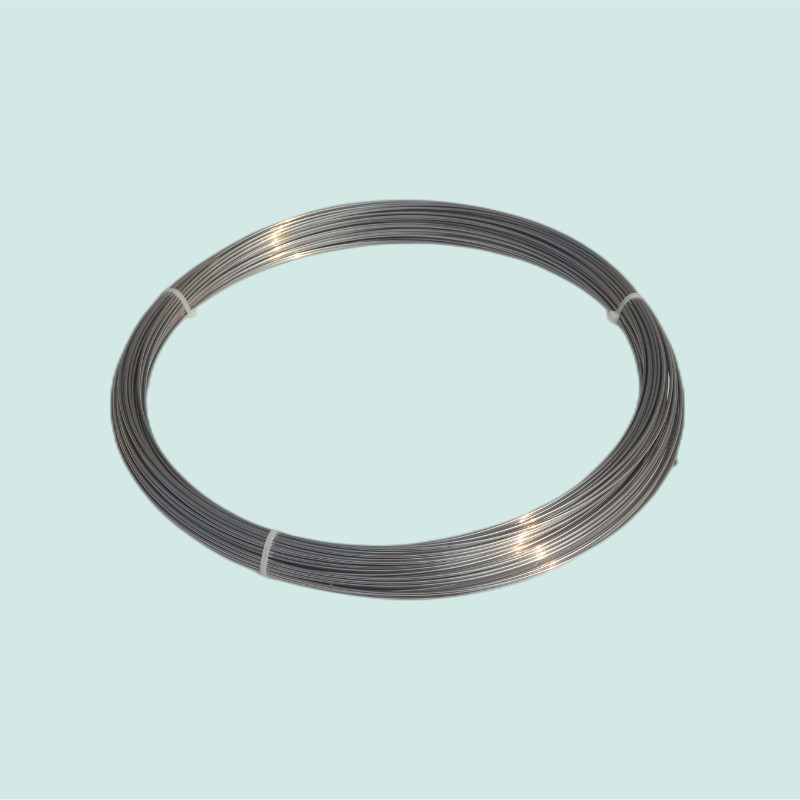

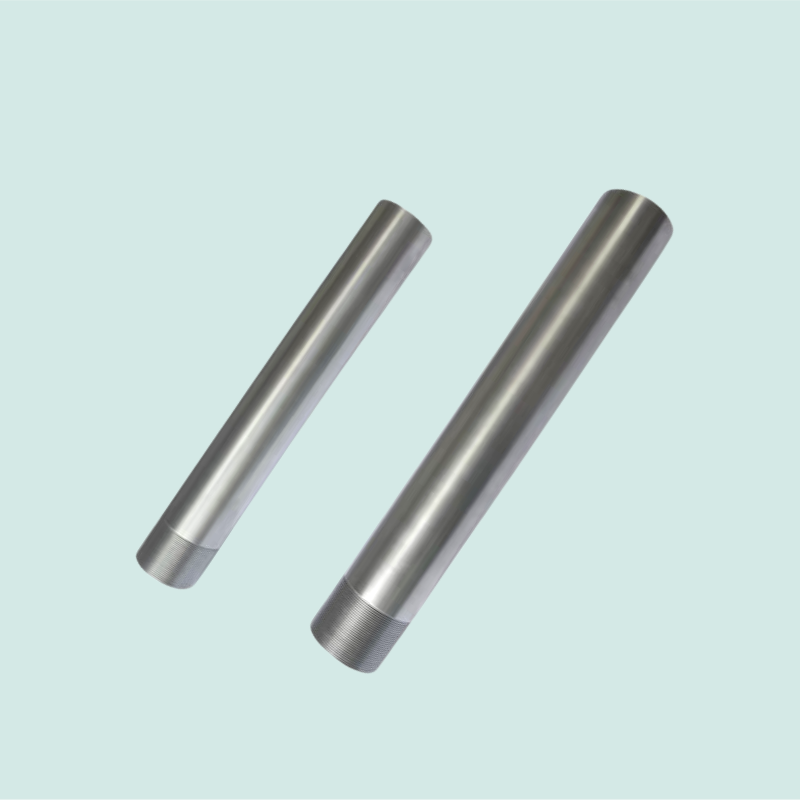

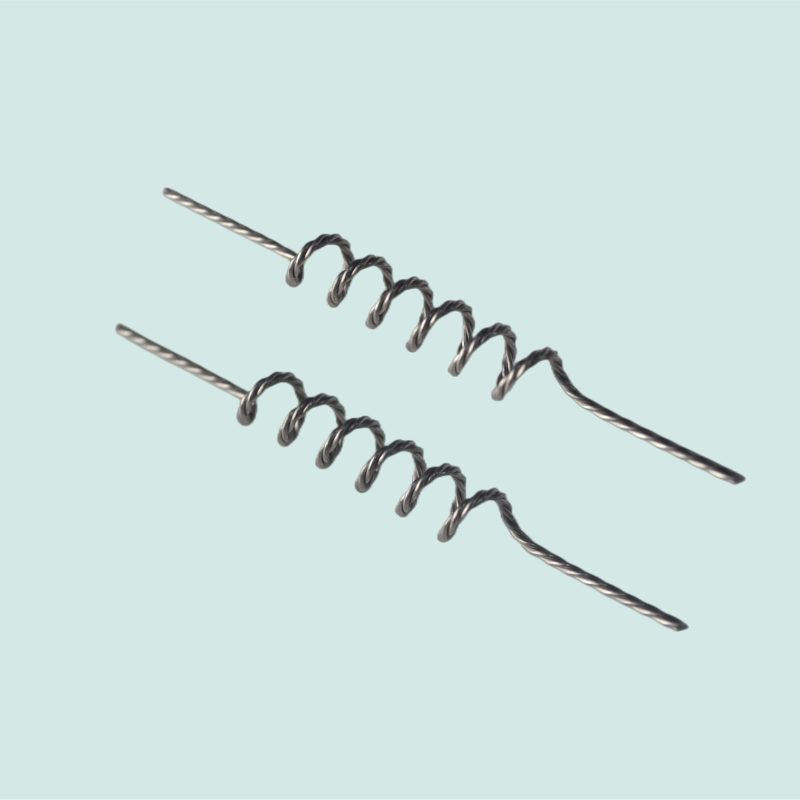

As the heat insulation component in the vacuum furnace , the biggest function of the heat shield is to block and reflect the heat in the furnace . Therefore , high-purity , accurate size , smooth surface, easy assembly , and reasonable design of heat shields are very important . Molybdenum heat shields are generally produced and processed with 0.5-1.2 mm molybdenum sheets . Generally, there are 4-6 layers. The inner layer of the furnace is made of high-temperature molybdenum TZM material with a thickness of 1.2 mm . Molybdenum strips are used to separate the layers with a space of 7mm . Other molybdenum heat shields are made of 0.5 – 0.8 mm MO1 material . Fasten them with molybdenum screws or molybdenum wire rods.

Product Parameters

| Products name | Molybdenum heat shield |

| Available material | Tungsten、Molybdenum、MoLaTZM、SS304(Stainless steel) |

| Thicknes | 0.2~0.5~1mm |

Design points of metal heat shield

| Material thermal properties | The maximum temperature of the selected metal material should be greater than the ambient working temperature, and the thermal deformation of the metal should be small. When the temperature is higher than 900℃, tungsten, molybdenum and tantalum sheets are generally used. Below 900℃, stainless steel sheet is generally used |

| material blackness | Choose a material with low blackness, the reflection effect of the surface is better, and the surface finish is higher. |

| Material thickness | The thickness of the screen should be as thin as possible. Molybdenum is generally 0.2~0.5mm, and stainless steel sheet is generally 0.5~1mm |

| material price | Under the condition of meeting the working temperature, the cost should be considered |

| Determination of the number of layers of heat shield | With the increase of the number of layers, the heat loss will decrease, the cost will increase, the structure will be complicated, and the vacuum degree will be more difficult to meet the working requirements. Increase to three layers to improve about 8%. The number of layers is not the better, and it should be considered comprehensively. The working temperature is 1000 ℃, and a maximum of 6 layers of screens can be used. |

| Spacing between each layer of heat shield | The spacing should be minimized. The thermal effect of increasing the distance is not large. If the spacing is too small, the two layers of heat shields will be connected together due to thermal deformation. Reduce the spacing, generally about 10mm |

| connection between each layer | Each layer of heat shield should be connected, and it should be ensured that the contact area of the connection is not too large, which will reduce the thermal efficiency. Use bushings and washers to connect each layer. |

| Maintenance of heat shields | The heat shield should be designed to be easily removable, and the thermal expansion and contraction properties of the material should also be considered. |

| The distance between the first screen and the radiating surface | Generally 50~100mm |

| The distance between the outermost screen and the circulating water wall | Generally 100~150mm |

Order Information

Inquiries and orders should include the following information

● Drawing of the Molybdenum isolation screen

● Material of the screen( W, Mo, Ta or SS304)

● Quantity

Product detail pictures:

Related Product Guide:

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and development, we are going to build a prosperous future alongside one another with your esteemed enterprise for Leading Manufacturer for Black Mo1 Molybdenum Wire - Molybdenum heat shield – WINNERS , The product will supply to all over the world, such as: moldova, Uruguay, Guatemala, Our factory covers an area of 12,000 square meters, and has a staff of 200 people, among which there are 5 technical executives. We are specialized in producing.We have rich experience in export. Welcome to contact us and your enquiry will be replied as soon as possible.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.