Introducing the Tungsten Evaporation Filament – Your Gateway to Precision and Reliability in Thin Film Deposition!

Introducing the Tungsten Evaporation Filament – Your Gateway to Precision and Reliability in Thin Film Deposition!,

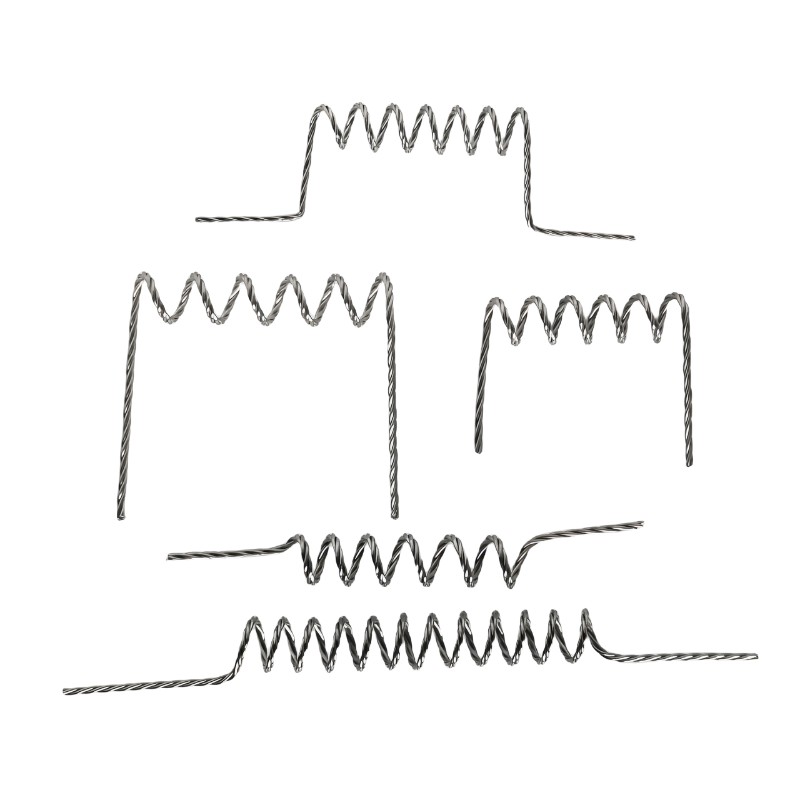

Tungsten Evaporation Filament coil,

Tungsten Filaments Coil Information

| Product Name | Tungsten Evaporation Filaments |

| Purity | W≥99.95% |

| Density | 19.3g/cm³ |

| Melting Point | 3410°C |

| Strands | φ0.76X3, φ0.81X3, φ1.0X3, φ1.0X2, Can be customized. |

| MOQ | 3Kg |

| Note: Special shapes of tungsten filaments can be customized according to your needs. | |

Example Drawing

|

Shape |

Straight, U Shape, Can be customized |

|

Number of Strands |

1, 2, 3, 4 |

|

Coils |

4, 6, 8, 10 |

|

Diameter of Wires(mm) |

φ0.76, φ0.81, φ1 |

|

Length of Coils |

L1 |

|

Length |

L2 |

|

ID of Coils |

D |

|

Note: other specifications and filament shapes can be customized. |

|

Our Advantages

The tungsten evaporation filaments produced by our company have high purity, no pollution, good film deposition effect, low power and low price, and are suitable for various vacuum evaporation equipment. We also provide diverse customized services.

Classification of Tungsten Filament Heaters

We provide evaporation sources and evaporation materials for PVD coating & Optical coating, these products include:

| Electron Beam Crucible Liners | Tungsten Coil Heater | Tungsten Cathode Filament |

| Thermal Evaporation Crucible | Evaporation Material | Evaporation Boat |

Don’t have the product you need? Please contact us, we will solve it for you.

Payment & Shipping

→PaymentSupport T/T, PayPal, Alipay, WeChat Pay, etc. Please negotiate with us for other payment methods.

→ShippingSupport FedEx, DHL, UPS, sea freight, and air freight, you can customize your transportation plan, and we will also provide cheap transportation methods for your reference.

Do you want to know more about our products?

Contact Me

Amanda│Sales Manager

E-mail: amanda@winnersmetals.com

Phone: 0086 156 1977 8518(WhatsApp/Wechat)

If you want to know more details and prices of our products, please contact our sales manager, she will reply to you as soon as possible (usually within 24 hours), of course, you can also click the “REQUEST A QUOTE” button, or contact us directly by email us(Email:info@winnersmetals.com).

Introducing the Tungsten Evaporation Filament – Your Gateway to Precision and Reliability in Thin Film Deposition!

Key Features:

High-Temperature Stability: The Tungsten Evaporation Filament boasts exceptional high-temperature stability, making it an ideal choice for thin film deposition processes. Its elevated melting point ensures consistent performance under extreme heat conditions.

Extended Lifespan: With its remarkable heat-resistant properties, the Tungsten Evaporation Filament is engineered for a prolonged lifespan. This longevity is crucial in thin film deposition applications, minimizing the frequency of replacements and reducing operational costs.

High Evaporation Efficiency: Leveraging the high melting point and stability of tungsten, this filament enhances evaporation efficiency. It facilitates the production of precise and uniform thin films, meeting the stringent requirements of various industries such as electronics, optics, and materials science.

Versatile Applications: Beyond thin film deposition, the Tungsten Evaporation Filament finds extensive use in electron beam sources, thermal evaporation systems, and other applications demanding high-temperature stability and durability. Its versatility makes it a go-to solution across multiple scientific and industrial domains.

Advanced Manufacturing: Crafted using advanced manufacturing processes, this filament guarantees quality and consistency. Precision engineering ensures that each filament meets the highest standards, providing reliable performance in diverse environments.

Environmental Friendliness: Tungsten is a recyclable material, and the production and usage of Tungsten Evaporation Filaments generate relatively minimal waste. This aligns with the growing emphasis on environmental sustainability, making it a responsible choice for your thin film deposition needs.

In conclusion, the Tungsten Evaporation Filament stands out for its high-temperature stability, extended lifespan, superior evaporation efficiency, and broad applicability. As a high-performance solution, it plays a pivotal role in thin film deposition processes, offering a reliable and precise method for various industrial and scientific applications. Choose the Tungsten Evaporation Filament for unparalleled quality and performance in your thin film deposition endeavors.