Introducing our Cutting-Edge Evaporation Coils – Redefining Efficiency in Thin Film Deposition!

Introducing our Cutting-Edge Evaporation Coils – Redefining Efficiency in Thin Film Deposition!,

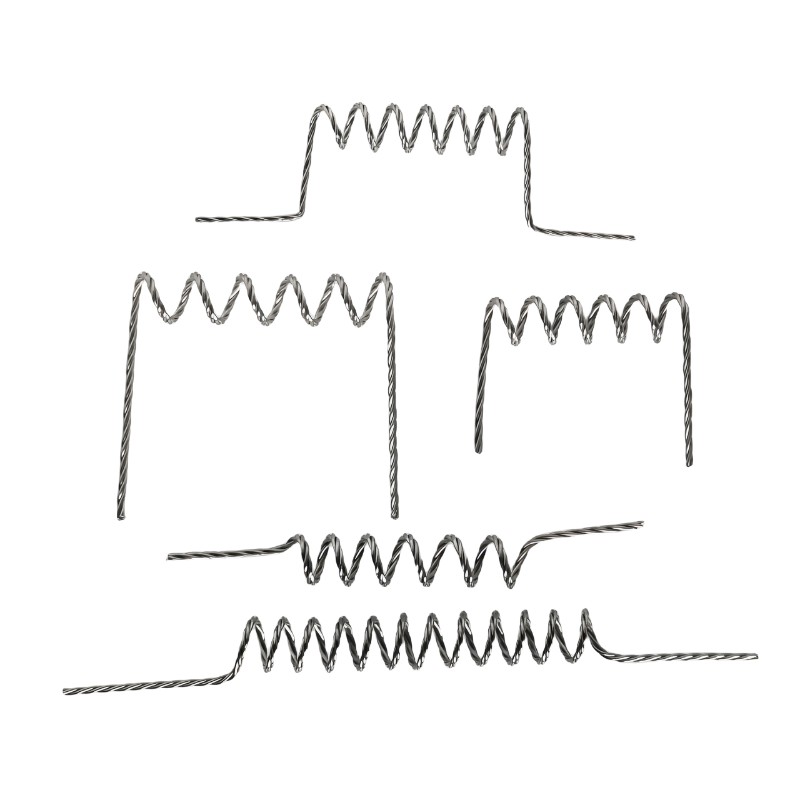

Evaporation Coils,

Tungsten Filaments Coil Information

| Product Name | Tungsten Evaporation Filaments |

| Purity | W≥99.95% |

| Density | 19.3g/cm³ |

| Melting Point | 3410°C |

| Strands | φ0.76X3, φ0.81X3, φ1.0X3, φ1.0X2, Can be customized. |

| MOQ | 3Kg |

| Note: Special shapes of tungsten filaments can be customized according to your needs. | |

Example Drawing

|

Shape |

Straight, U Shape, Can be customized |

|

Number of Strands |

1, 2, 3, 4 |

|

Coils |

4, 6, 8, 10 |

|

Diameter of Wires(mm) |

φ0.76, φ0.81, φ1 |

|

Length of Coils |

L1 |

|

Length |

L2 |

|

ID of Coils |

D |

|

Note: other specifications and filament shapes can be customized. |

|

Our Advantages

The tungsten evaporation filaments produced by our company have high purity, no pollution, good film deposition effect, low power and low price, and are suitable for various vacuum evaporation equipment. We also provide diverse customized services.

Classification of Tungsten Filament Heaters

We provide evaporation sources and evaporation materials for PVD coating & Optical coating, these products include:

| Electron Beam Crucible Liners | Tungsten Coil Heater | Tungsten Cathode Filament |

| Thermal Evaporation Crucible | Evaporation Material | Evaporation Boat |

Don’t have the product you need? Please contact us, we will solve it for you.

Payment & Shipping

→PaymentSupport T/T, PayPal, Alipay, WeChat Pay, etc. Please negotiate with us for other payment methods.

→ShippingSupport FedEx, DHL, UPS, sea freight, and air freight, you can customize your transportation plan, and we will also provide cheap transportation methods for your reference.

Do you want to know more about our products?

Contact Me

Amanda│Sales Manager

E-mail: amanda@winnersmetals.com

Phone: 0086 156 1977 8518(WhatsApp/Wechat)

If you want to know more details and prices of our products, please contact our sales manager, she will reply to you as soon as possible (usually within 24 hours), of course, you can also click the “REQUEST A QUOTE” button, or contact us directly by email us(Email:info@winnersmetals.com).

Introducing our Cutting-Edge Evaporation Coils – Redefining Efficiency in Thin Film Deposition!

Unleash Efficiency and Precision:

Step into the future of thin film deposition with our state-of-the-art Evaporation Coils. Engineered for excellence, these coils are designed to provide unparalleled efficiency, precision, and reliability in diverse coating applications.

1. Advanced Material Composition:

Our Evaporation Coils are meticulously crafted from high-quality materials, ensuring superior performance in a variety of deposition processes. The advanced material composition guarantees durability, thermal stability, and optimal functionality in challenging environments.

2. Precision Deposition for High-Quality Films:

Achieve precise and uniform coatings with our Evaporation Coils. Whether you’re working with metals, alloys, or organic materials, these coils enable controlled evaporation, resulting in high-quality films that meet the most stringent industry standards.

3. Customizable Configurations:

Recognizing the uniqueness of each application, our Evaporation Coils come in customizable configurations. Tailor the coil specifications to fit seamlessly into your deposition system, ensuring a perfect match for your specific requirements.

4. Enhanced Thermal Efficiency:

Experience superior thermal efficiency with our Evaporation Coils. Engineered to withstand high temperatures, these coils contribute to stable and consistent performance during the evaporation process, reducing the risk of thermal fluctuations.

5. Versatile Applications:

Our Evaporation Coils find applications across a wide spectrum of industries, from electronics and optics to materials science. Their versatility makes them suitable for a range of deposition techniques, including thermal evaporation, electron beam evaporation, and more.

6. Streamlined Integration:

Upgrade your deposition system effortlessly with coils designed for seamless integration. Our Evaporation Coils are compatible with various deposition chambers, facilitating a smooth transition and enhancing the overall efficiency of your thin film deposition processes.

7. Expert Guidance and Support:

Our commitment to your success extends beyond the product. Rely on our expert support team to guide you through the coil selection process and provide assistance in optimizing performance for your specific applications.

8. Future-Ready Innovation:

Stay ahead of technological advancements with our Evaporation Coils. As the landscape of thin film deposition evolves, our commitment to innovation ensures that our coils remain at the forefront of emerging technologies.

Elevate your thin film deposition processes with the efficiency and precision of our Evaporation Coils – where advanced materials meet cutting-edge technology. Choose coils that redefine the standards of excellence in thin film deposition. Your journey to enhanced efficiency starts here.