Hot sale Factory Molybdenum Facts - Glass melting electrode – WINNERS

Hot sale Factory Molybdenum Facts - Glass melting electrode – WINNERS Detail:

Product Description

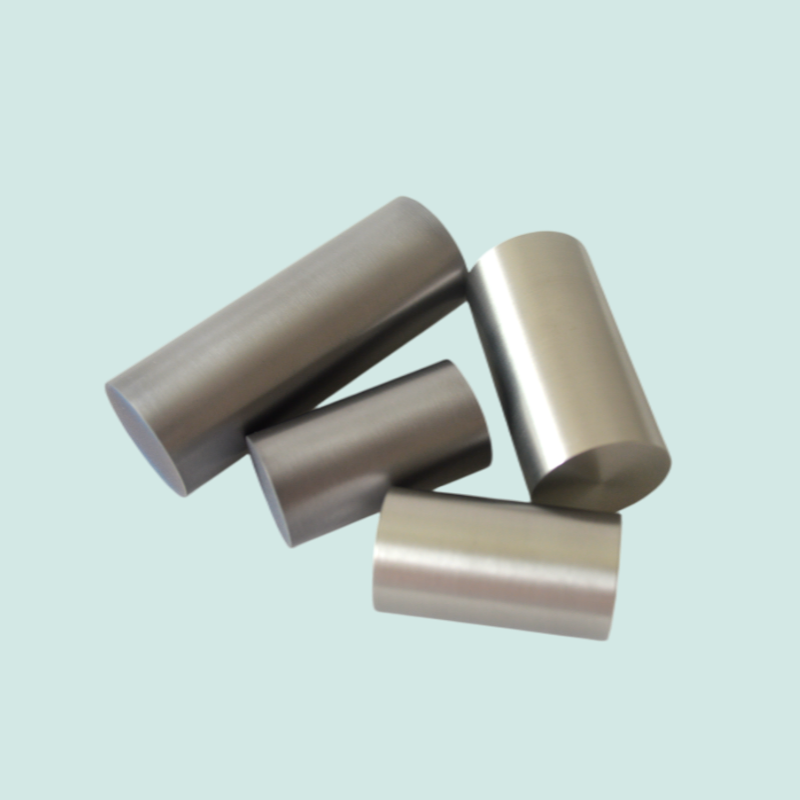

The main component of molybdenum electrode is molybdenum, which is obtained by powder metallurgy process. The international common molybdenum electrode composition content is 99.95%, and the density is greater than 10.15g/cm3 to ensure the quality of the glass and the service life of the electrode. The use of molybdenum electrodes to replace the original heavy oil and gas energy can effectively reduce environmental pollution and improve the quality of glass.

Product Parameters

|

Products name |

Molybdenum Electrode |

|

Diameter |

20~152.4mm |

|

Length |

Less than 1500mm |

|

Standard |

ASTM B387 |

|

Purity |

≥99.95% |

|

Surface |

Black,Polishing, Grinding bright |

|

Density |

10.15g/cm3 |

|

Technology |

Sintering,Forged |

|

MOQ |

1 piece |

Note: MoLa electrode and TZM Electrode are available for us too.

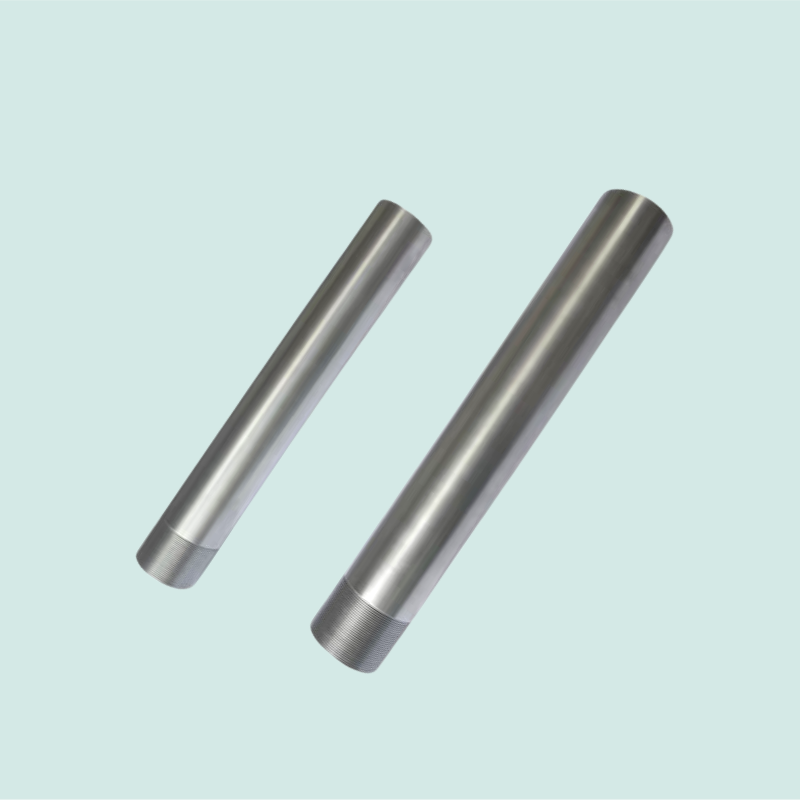

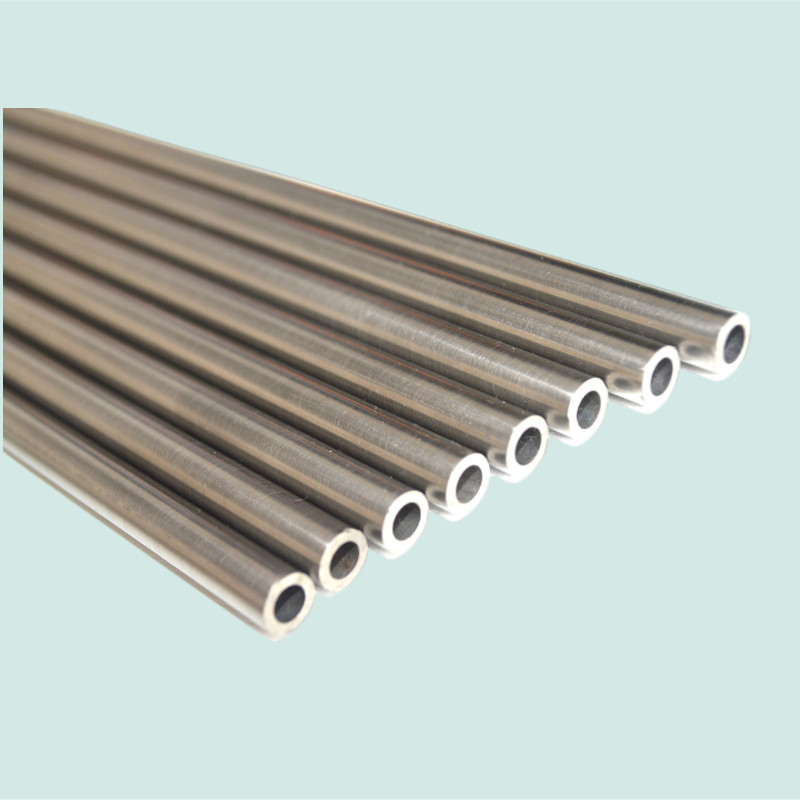

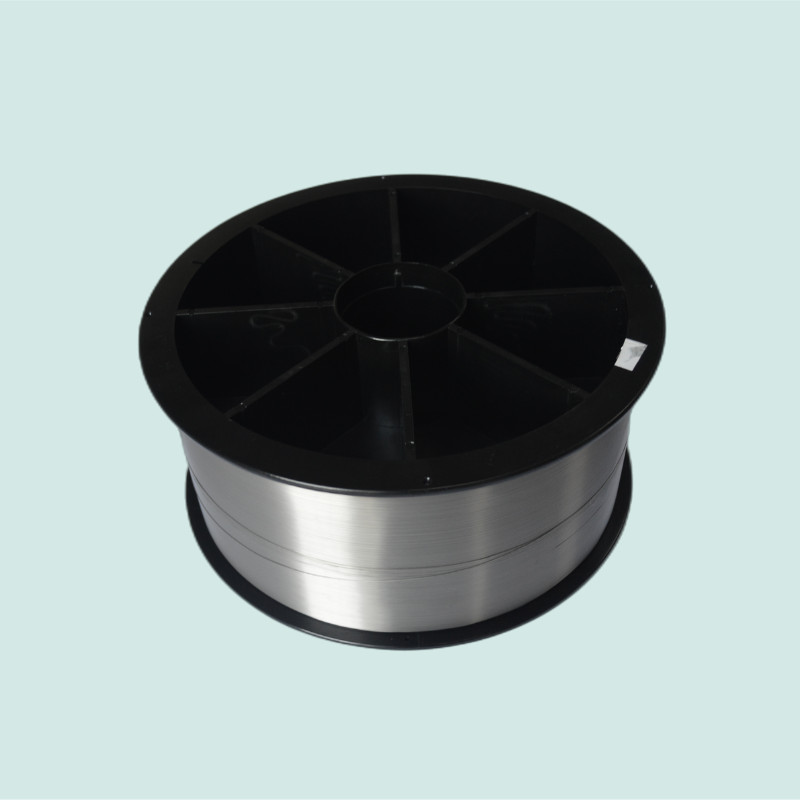

According to different shapes, molybdenum electrodes can be divided into electrode rods, electrode plates, electrode rods and threaded electrodes, etc., and their uses are slightly different. In heating equipment for fiberglass furnaces and liquid orifice panels. According to the different surface conditions, it can be divided into sintered molybdenum electrode (gray metallic luster on the surface), forged molybdenum electrode (black surface), car light molybdenum electrode (surface smooth and rough), alkali-washed molybdenum electrode (smooth surface), Polished molybdenum electrode (smooth surface), polished molybdenum electrode (bright and shiny surface), etc.

Main Feature

● Low coefficient of thermal expansion.

● High thermal and electrical conductivity.

● Reduces detrimental glass discoloring.

● Superior corrosion resistance.

● Good machined ability.

● Outstanding strength and stability at elevated temperatures up to 2000 °C.

Application

● Glass wool and thermal insulation cotton.

● optical glass, daily glass.

● Rare earth industry, glass fiber.

● Refractory fiber.

● Glass liquid and water cooling jacket.

Order Information

Inquiries and orders should include the following information.

● Surface of the Molybdenum Electrode( Black, Polishing or Grinding).

● Diameter, Length, Thread size or offering to us.

● Quantity (Even one piece we can provide).

Product detail pictures:

Related Product Guide:

Usually customer-oriented, and it's our ultimate focus on to be not only by far the most reliable, trustable and honest provider, but also the partner for our customers for Hot sale Factory Molybdenum Facts - Glass melting electrode – WINNERS , The product will supply to all over the world, such as: Bulgaria, Algeria, Bangkok, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we are going to continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.