High Quality for Molybdenum Mini Tubes - Pure Molybdenum Wire Manufacture – WINNERS

High Quality for Molybdenum Mini Tubes - Pure Molybdenum Wire Manufacture – WINNERS Detail:

Product Description

Molybdenum has a very high melting point, low thermal expansion and high thermal conductivity, so it is used in many different industries.

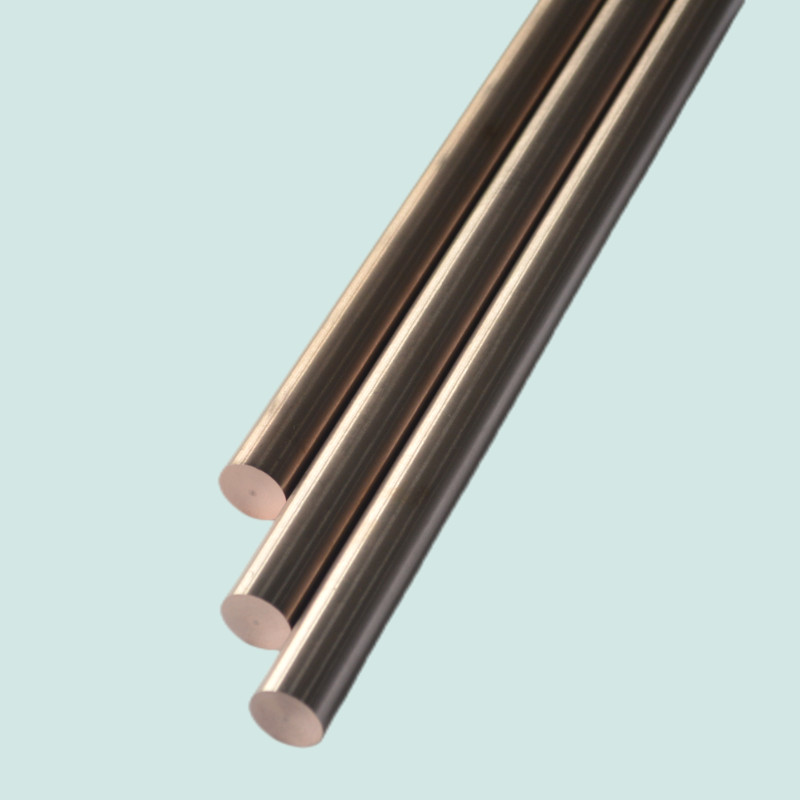

Molybdenum wire is divided into spraying molybdenum wire, wire cutting molybdenum wire and electric light source molybdenum wire according to the purpose. General molybdenum wire processing plants use ammonium molybdate or high-purity molybdenum oxide as raw materials, and have the following production capacity: 1. Molybdenum powder production: use ammonium molybdate or high-purity molybdenum oxide as raw materials to reduce molybdenum powder. 2. Molybdenum rod production: Molybdenum powder is isostatically pressed and then sintered into molybdenum rods at high temperature. 3. Thick molybdenum wire: The molybdenum bar is rolled at high temperature into thick wire of 5-6mm. 4. Thin molybdenum wire: The thick wire of 5-6mm is stretched one or more times to finally produce the size required by the customer.

Product Parameters

|

Products name |

Molybdenum wire |

|

Grade |

Mo1, MoLa |

|

Standard |

GB/T 4181-2017 |

|

Purity |

99.95%, 99.92% |

|

Density |

10.2g/cm³ |

|

MOQ |

1Kg |

|

Surface |

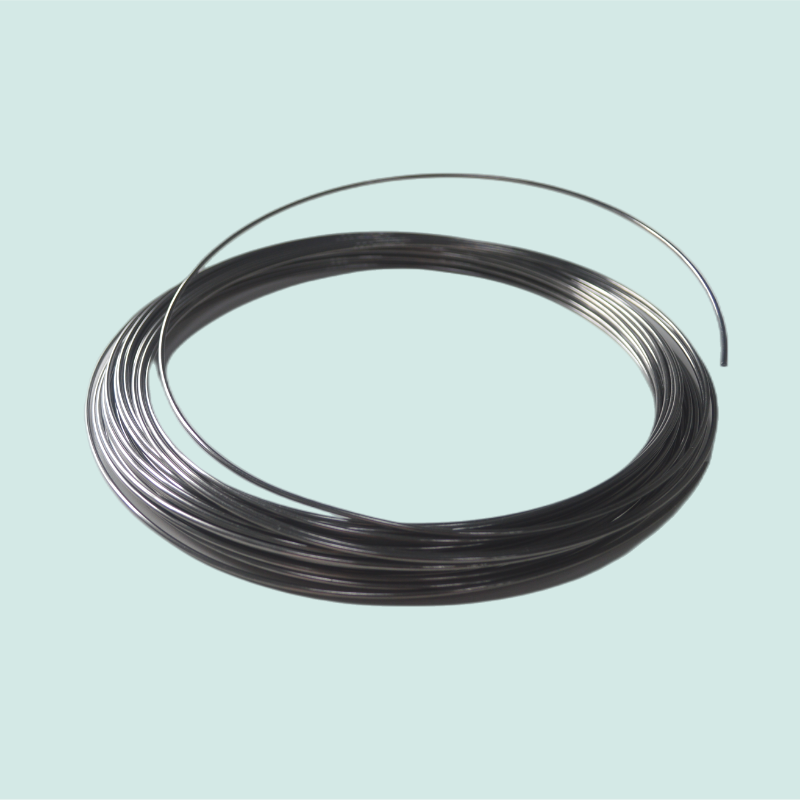

Black wire, bright wire |

|

Technology process |

drawing, polishing |

|

Application |

Spray molybdenum wire, EDM cutting wire, molybdenum wire for high temperature furnace |

Application

● Forming material Cutting, H2 Furnaces, Heater Rod Guide Rod Hooks, Mandrels, Wires, etc.

● High temperature brackets, guide rods, heating rods in the furnace, etc.

● Molybdenum wire is mainly used in high temperature thermal field of molybdenum furnace and tube socket.

● EDM wire cutting.

● Spray Molybdenum Wire Automotive Industry.

Product Specifications

|

Application field |

Diameter |

|

EDM wire cutting |

0.16mm, 0.18mm, 0.2mm |

|

Spray molybdenum wire |

1.4mm, 2.0mm, 2.5mm, 3.0mm, 3.17mm |

|

Heating elements of the vacuum furnace |

0.5mm, 0.6mm, 1.0mm, 2.0mm, 3.0mm, 6.35mm |

EDM Order Information

Inquiries and orders should include the following information.

● Surface: Back or bright wire.

● Diameter, weight or Length.

● Other special demand.

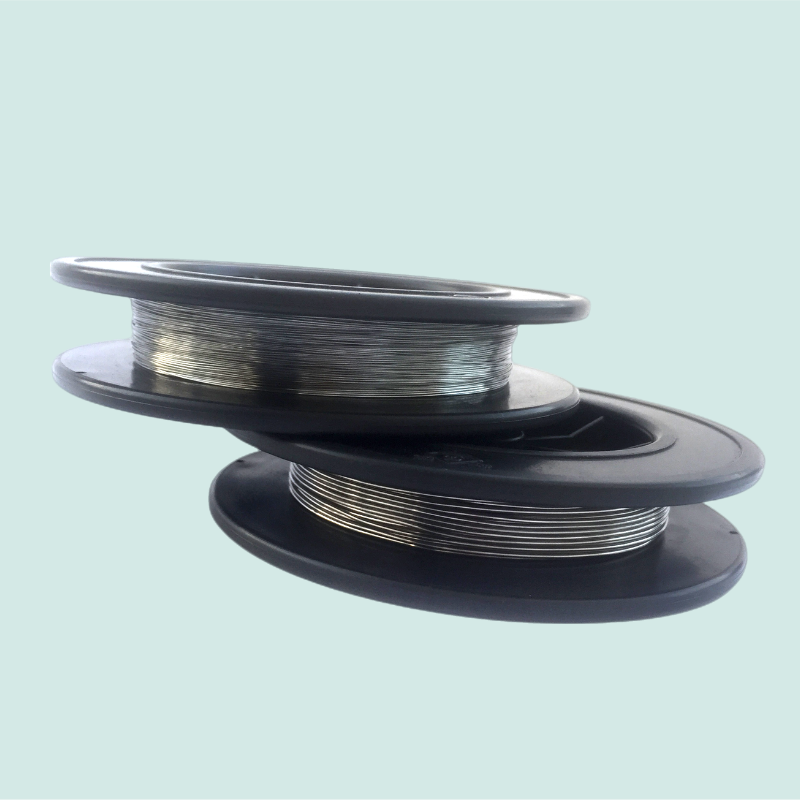

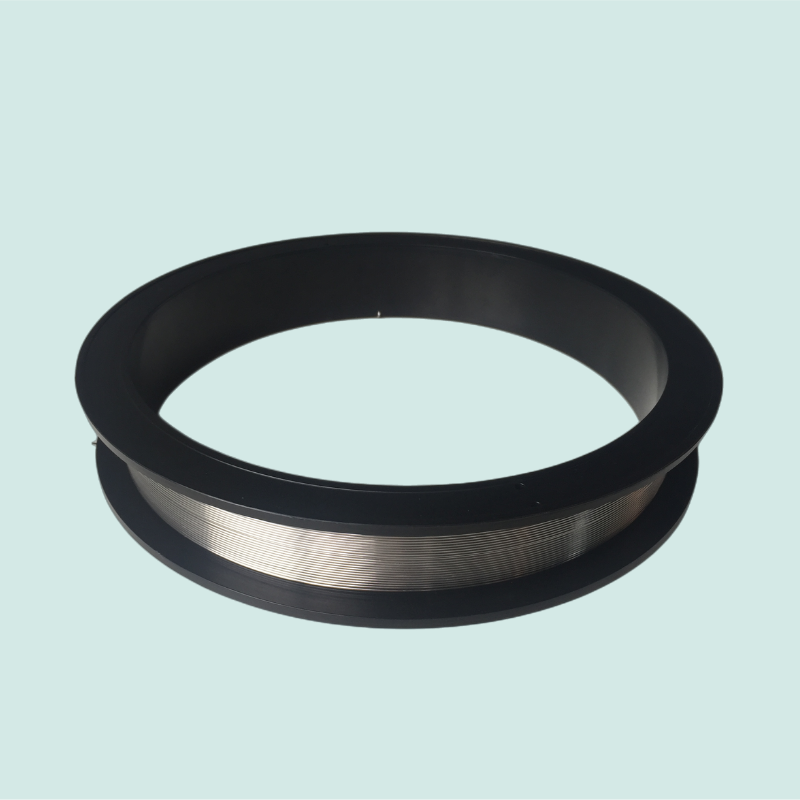

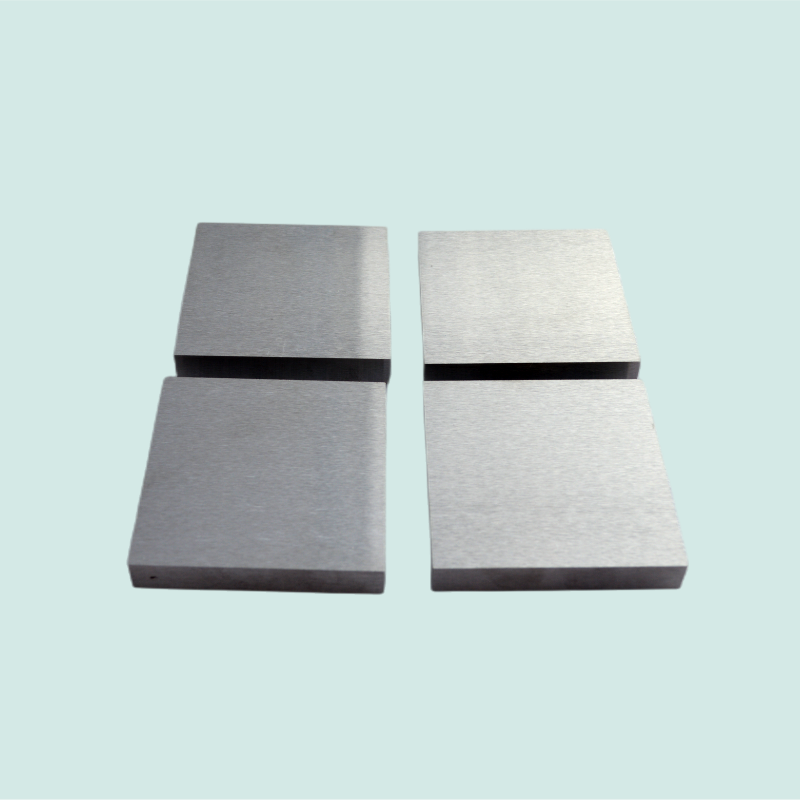

Product detail pictures:

Related Product Guide:

All we do is usually connected with our tenet " Consumer initial, Rely on 1st, devoting around the food stuff packaging and environmental safety for High Quality for Molybdenum Mini Tubes - Pure Molybdenum Wire Manufacture – WINNERS , The product will supply to all over the world, such as: Jersey, Hanover, South Africa, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, be sure to feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our merchandise, make sure you feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.