Free sample for Seamless Tungsten Pipe - Smelting Tungsten Crucibles Wolfram Liner – WINNERS

Free sample for Seamless Tungsten Pipe - Smelting Tungsten Crucibles Wolfram Liner – WINNERS Detail:

Product Description

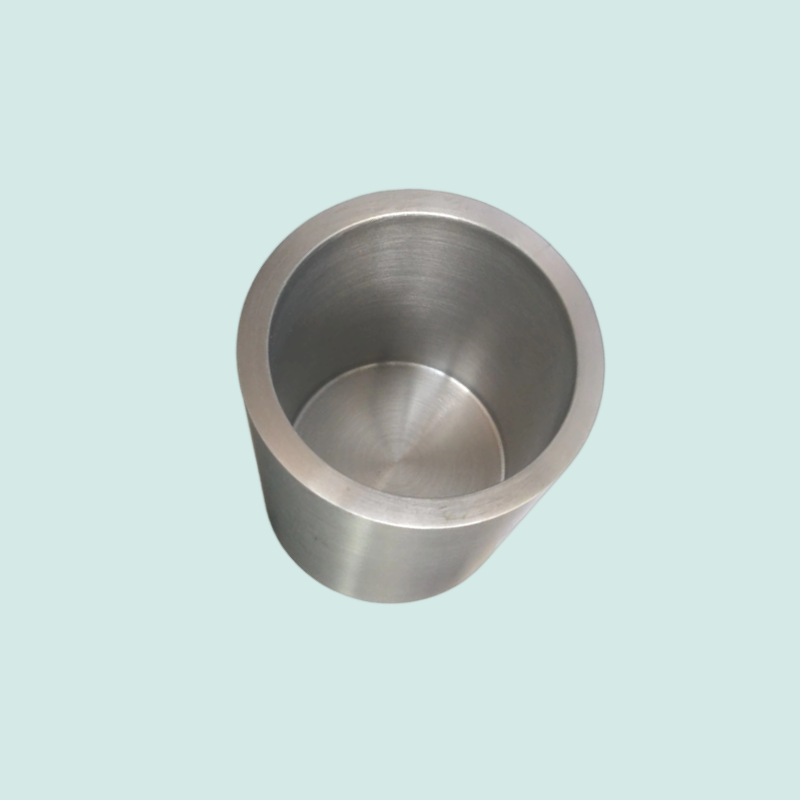

Tungsten crucible

The melting point of tungsten is as high as 3410°C. Therefore, tungsten crucibles are widely used as core containers in industrial furnaces such as sapphire single crystal growth furnaces, quartz glass melting furnaces, and rare earth smelting furnaces. The working temperature environment is generally above 2000°C.

Tungsten crucibles with high purity, high density, no internal cracks, precise dimensions, and smooth inner and outer walls are particularly important for sapphire single crystal growth furnaces. High-quality tungsten crucibles play a key role in the success rate of seed crystals, quality control of crystal pulling, and service life during the growth of sapphire crystals.

Product Parameters

|

Product name |

Tungsten crucible |

|

Grade |

W1, W2 |

|

Density |

≥18.5g/cm³ |

|

Purity |

≥99.95% |

|

Process technology |

Sintering, Punch, Spun, machine |

|

Operating temperature |

<2400 |

Application

Tungsten crucibles are widely used in:

■ Rare earth smelting. ■ Evaporation coating. ■ Quartz glass. ■ Electronic spraying. ■ Sapphire Crystal growth.

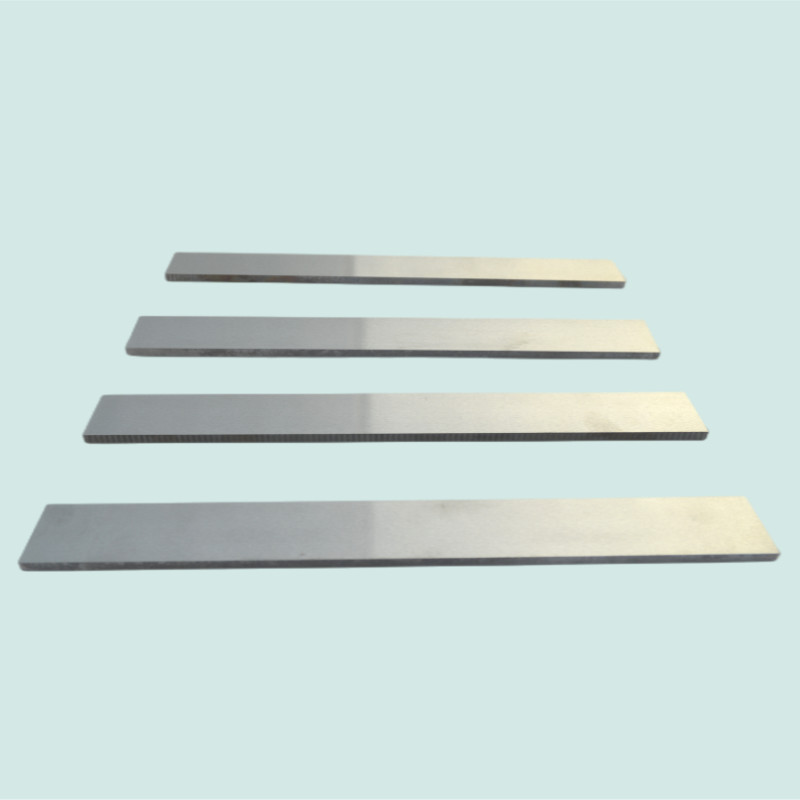

Product detail pictures:

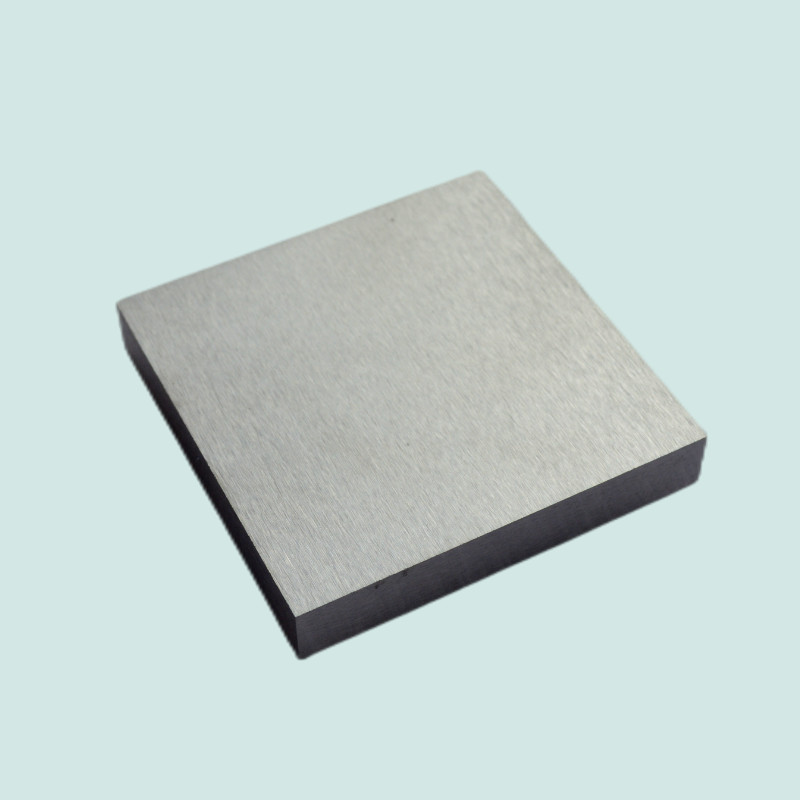

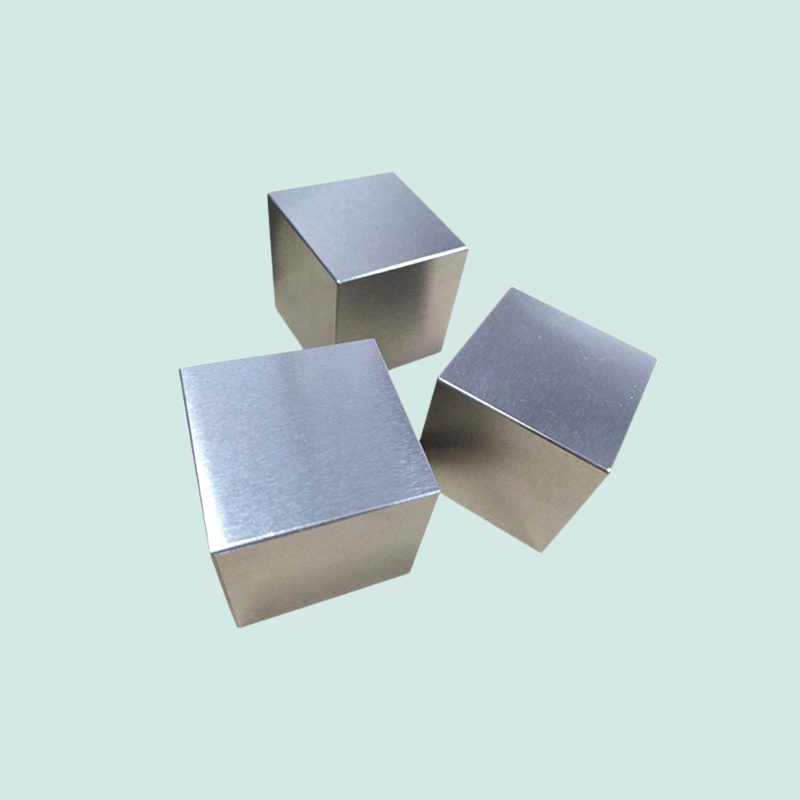

Related Product Guide:

As a result of ours specialty and service consciousness, our company has won a good reputation among customers all over the world for Free sample for Seamless Tungsten Pipe - Smelting Tungsten Crucibles Wolfram Liner – WINNERS , The product will supply to all over the world, such as: Hyderabad, Bulgaria, Swansea, We always stick to the tenet of "sincerity, high quality, high efficiency, innovation". With years of efforts, we have established friendly and stable business relationships with worldwide customers. We welcome any of your inquiries and concerns for our products, and we are sure that we will offer just what you want, as we always believe that your satisfaction is our success.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!