Fast delivery Molybdenum Fastener - Pure Molybdenum Crucible for Rare Earth Smelting – WINNERS

Fast delivery Molybdenum Fastener - Pure Molybdenum Crucible for Rare Earth Smelting – WINNERS Detail:

Product Description

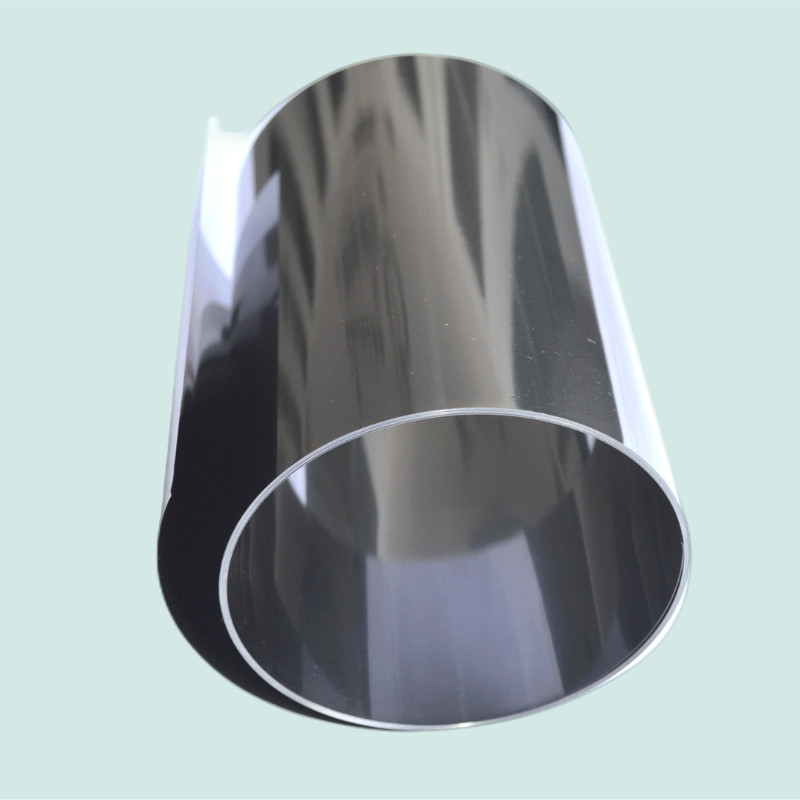

Molybdenum Crucible

The melting point of molybdenum is as high as 2610°C. Therefore, tungsten crucibles are widely used as core containers in industrial furnaces such as sapphire single crystal growth furnaces, quartz glass melting furnaces, and rare earth melting furnaces. The long-term working temperature is generally between 1200°C and 1800°C.

Molybdenum crucibles with high purity, high density, no internal cracks, precise dimensions, and smooth inner and outer walls are particularly important for sapphire single crystal growth furnaces. High-quality molybdenum crucibles play a key role in the success rate of seed crystals, quality control of crystal pulling, and service life during the growth of sapphire crystals.

Product Parameters

|

Products name |

Molybdenum crucibles |

|

Standard |

GB/T3462-2007 |

|

Grade |

Mo1 |

|

Purity |

≥99.95% |

|

Type |

Spinning Crucible, Machined Crucible, Welding Crucible |

|

MOQ |

1 piece or 1 set |

|

Surface |

Silver grey metal luster |

|

Operating temperature |

1200~1800℃ |

*Note: various sizes of molybdenum crucibles can be processed and customized according to customer requirements, and the high-precision requirements of users can be met through machining.

Molybdenum Crucible Process

Molybdenum powder→Sieving→Batching→Isostatic pressing→Rough turning processing→

Intermediate frequency sintering→Exquisite lathe processing

Application

■ Sapphire single crystal growth furnace. ■ Quartz glass melting furnace. ■ Rare earth smelting furnace.

Order Information

Inquiries and orders should include the following information:

■ Outer diameter, wall thickness, height of Moly crucibles.

■ Customized parts provide drawings or sample processing.

■ Select the crucible according to the actual needs.

Product detail pictures:

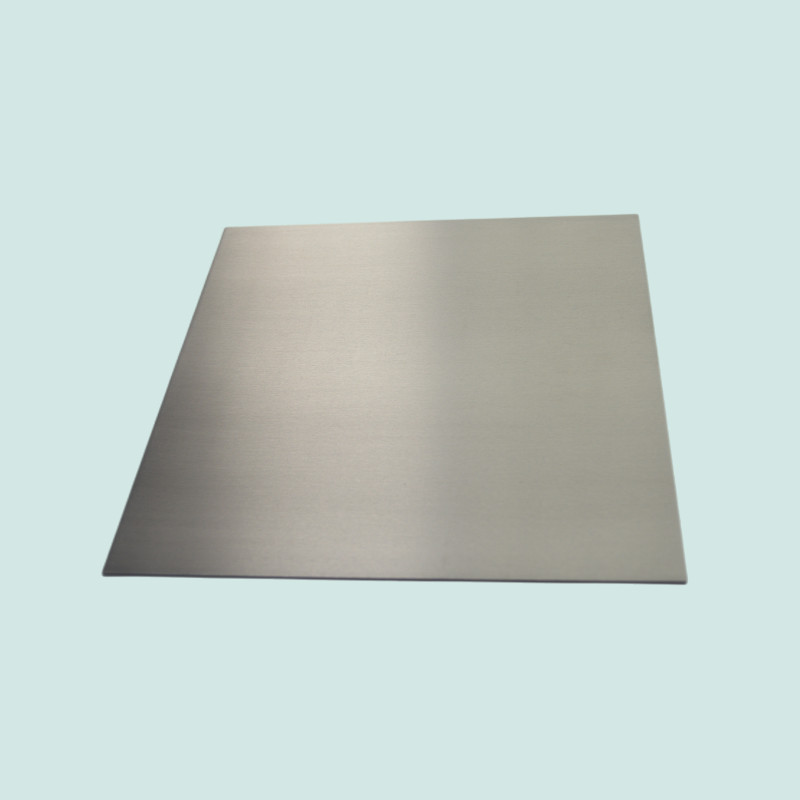

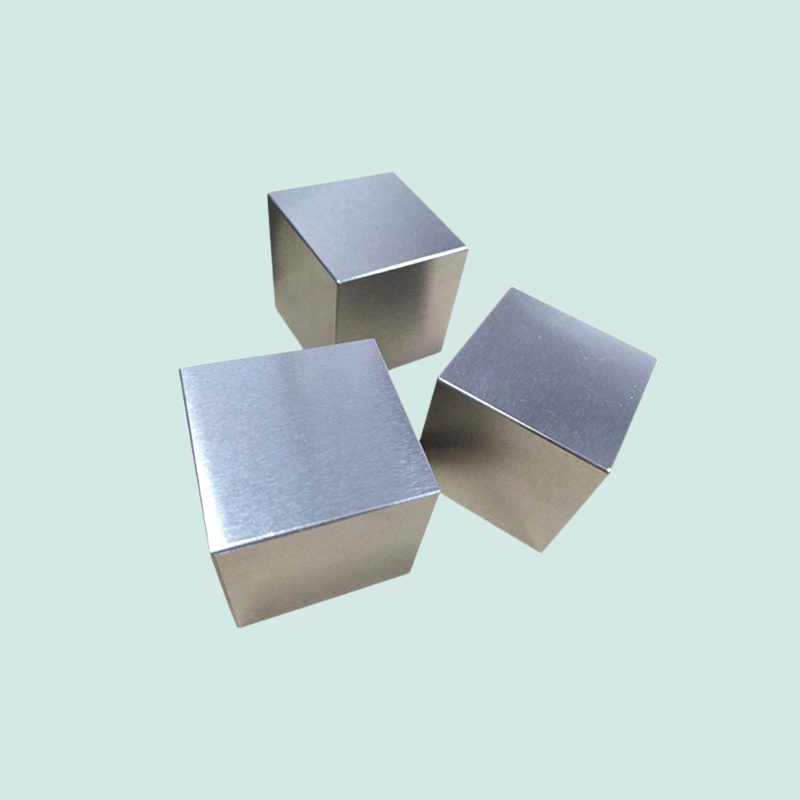

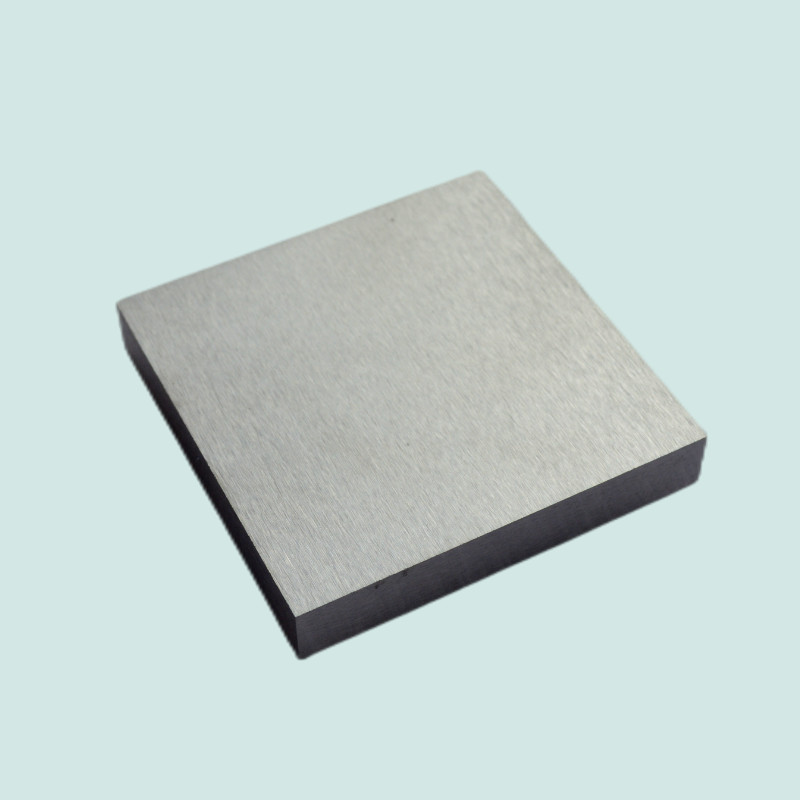

Related Product Guide:

We will devote ourselves to giving our esteemed buyers using the most enthusiastically thoughtful services for Fast delivery Molybdenum Fastener - Pure Molybdenum Crucible for Rare Earth Smelting – WINNERS , The product will supply to all over the world, such as: Greek, Belgium, Singapore, With the effort to keep pace with world's trend, we'll always endeavor to meet customers' demands. If you want develop any other new items, we can customize them to suit your needs. If you feel interest in any of our products and solutions or want develop new merchandise, you should feel free to contact us. We are looking forward to forming successful business relationship with customers all over the world.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.