Factory supplied Moly Seed Chuck - Factory price Tungsten based heavy alloy – WINNERS

Factory supplied Moly Seed Chuck - Factory price Tungsten based heavy alloy – WINNERS Detail:

Product Parameters

The powder metallurgy process is used to complete the production of tungsten-nickel-iron alloys in strict accordance with ISO 9001 quality standards. The products fully meet the specifications and requirements of AMS-T-21014 and ASTM-B-777-99 (MIL-T-21014).

Baoji Wennas can produce various large and special-shaped parts of high specific gravity alloy by isostatic pressing technology, various small products by extrusion, molding and injection molding technology, and various small products by forging, extrusion and rolling technology. It can provide various grades of high-density alloys for domestic and foreign users, and the technology has reached the domestic and international leading level.

Conventional tungsten nickel iron alloy properties

|

Grade |

chemical composition% |

Density (g/cm3) |

Tensile strength (MPa) |

Yield Strength (MPa) |

Elastic Modulus (%) |

HardnessMax (HRC) |

magnetic |

|

|

W |

NiFe |

|||||||

|

ATM1700 |

90 |

Bal |

16.85~17.25 |

≥758 |

≥517 |

≥5 |

32 |

yes |

|

ATM1750 |

92.5 |

Bal |

17.15~17.85 |

≥758 |

≥517 |

≥5 |

33 |

yes |

|

ATM1800 |

95 |

Bal |

17.75~18.35 |

≥724 |

≥517 |

≥3 |

34 |

yes |

|

ATM1850 |

97 |

Bal |

18.25~18.85 |

≥689 |

≥517 |

≥2 |

35 |

yes |

Application

Tungsten-nickel-iron alloy is widely used and has become the main tungsten-based heavy alloy with the largest amount. For general applications, such as counterweights, counterweights, radiation shielding devices, etc., sintered alloys are directly used; but for applications requiring high mechanical properties, tungsten-nickel-iron alloys require deformation processing and heat treatment to achieve strengthening.

● Tungsten-nickel-iron alloys are mainly used in the manufacture of gyroscope rotors, guide devices and shock absorbers for aviation and spacecraft;

● Die-casting molds, tool holders, boring bars and automatic watch weights for machinery manufacturing;

● Armor-piercing bullet cores for conventional weapons, rivet heads and switch contacts for electrical products;

● In addition, it is also used to manufacture various radiation shielding parts, etc.

Order Information

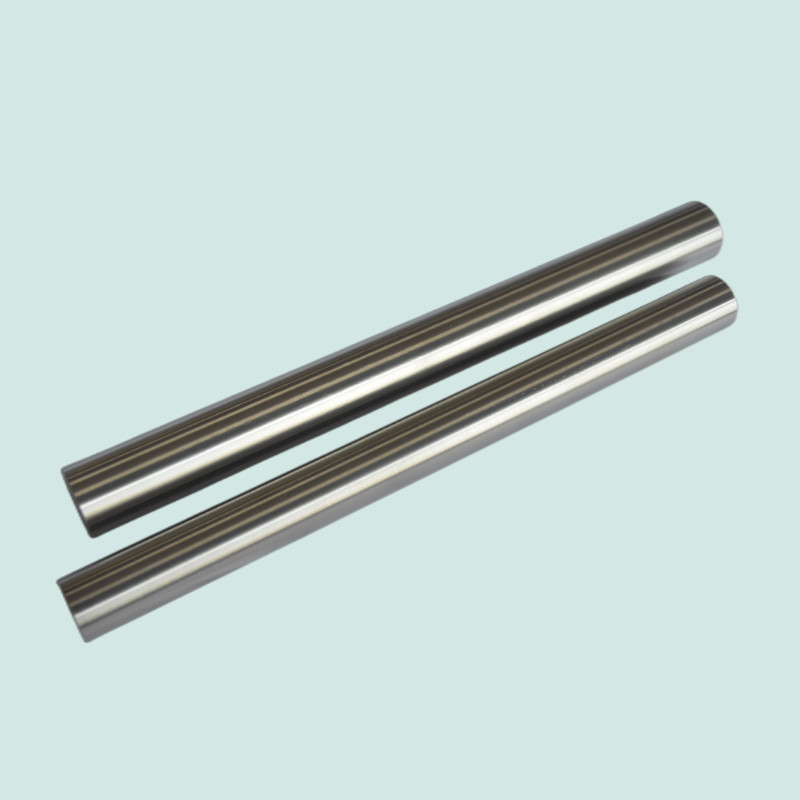

Inquiries and orders should include the following information

● Composition ratio of tungsten, nickel and Iron

● Diameter and Length

● Quantity

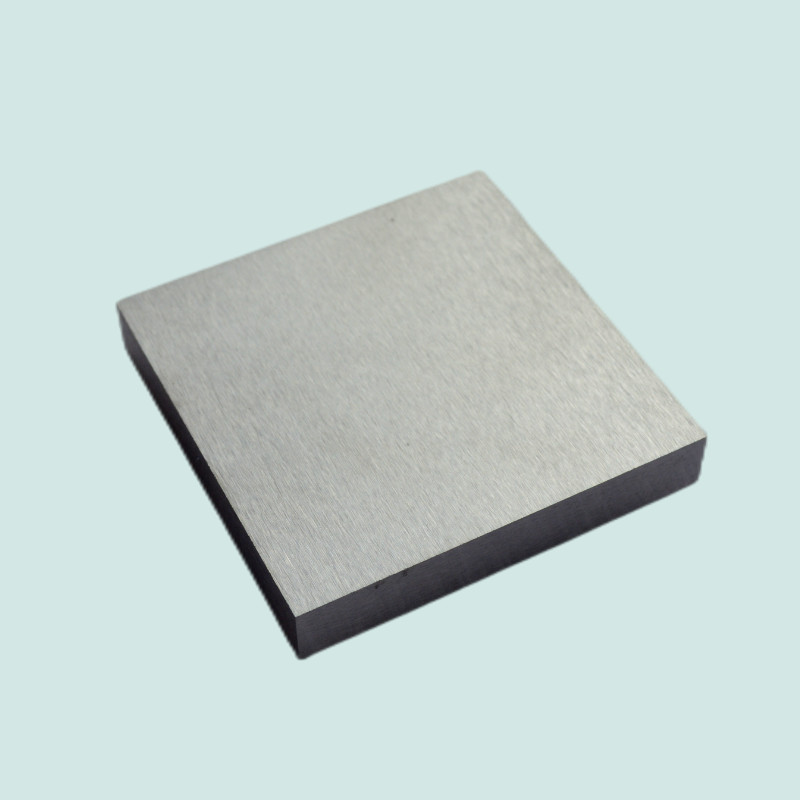

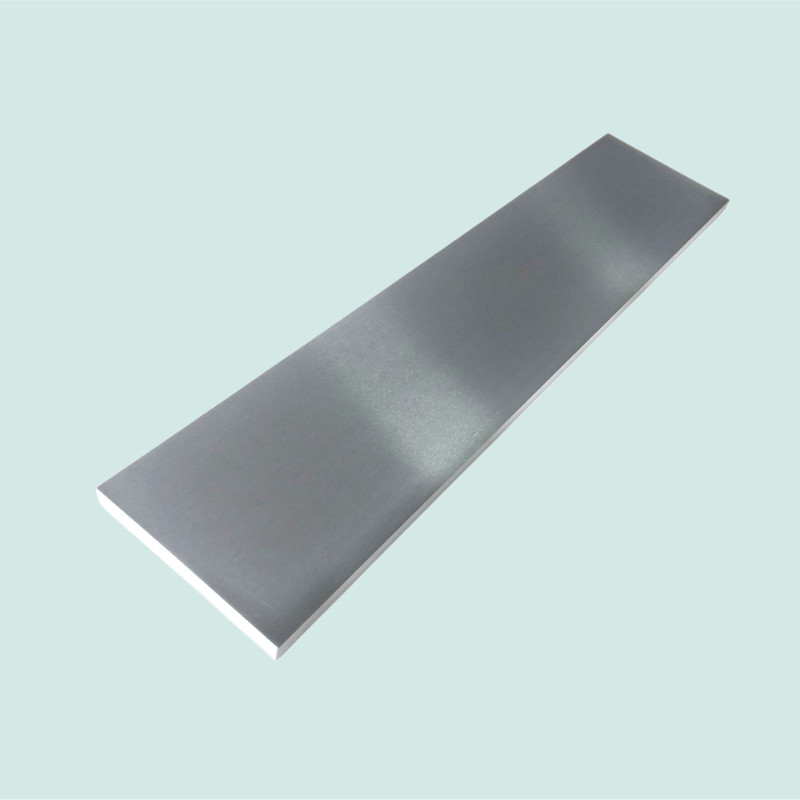

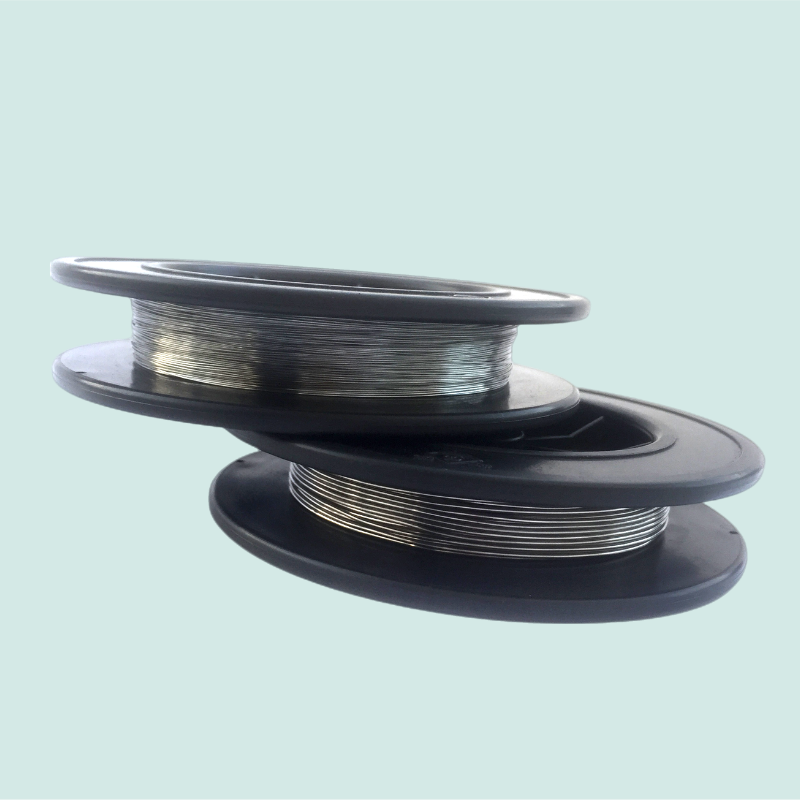

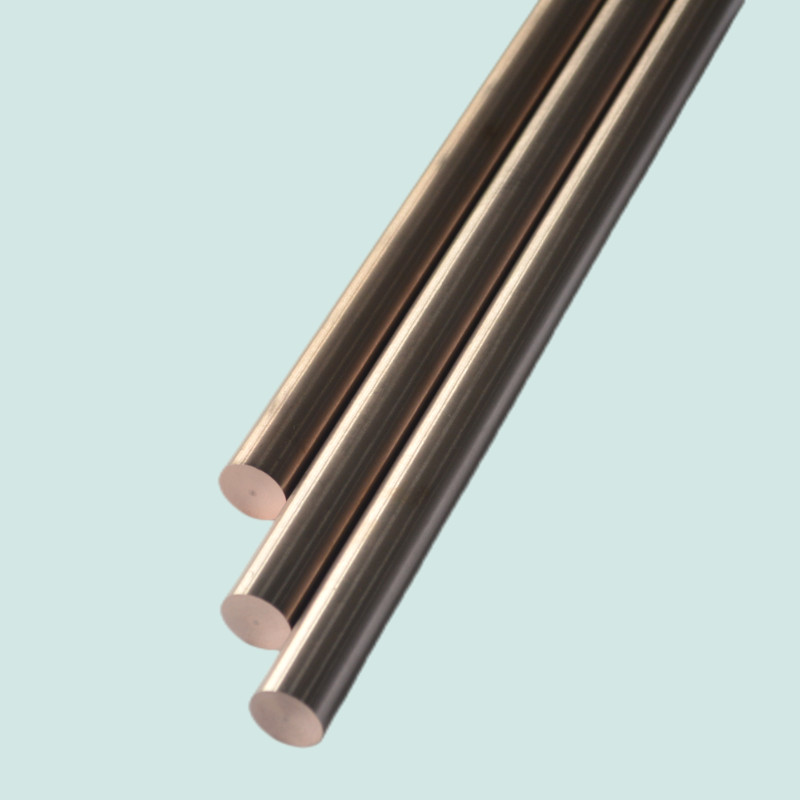

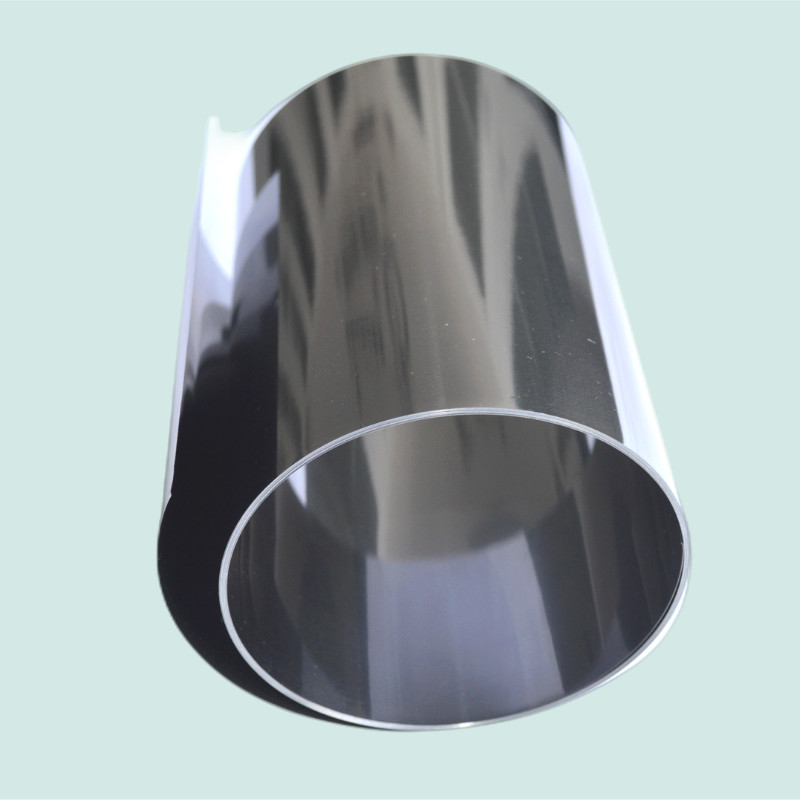

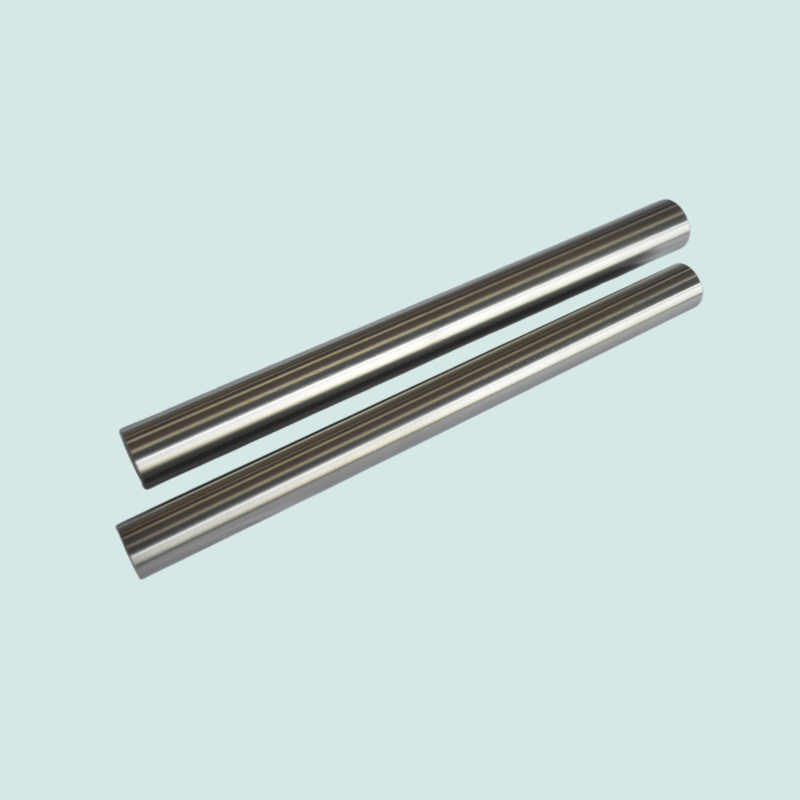

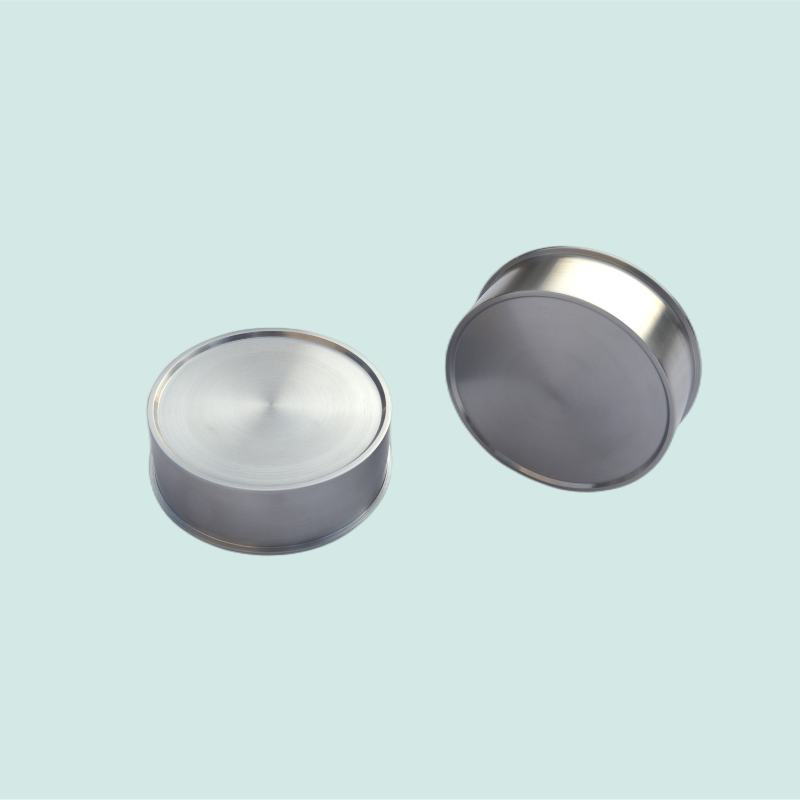

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our management ideal for Factory supplied Moly Seed Chuck - Factory price Tungsten based heavy alloy – WINNERS , The product will supply to all over the world, such as: Bahrain, Malawi, South Africa, Adhering to the principle of "Enterprising and Truth-Seeking, Preciseness and Unity", with technology as the core, our company continues to innovate, dedicated to providing you with the highest cost-effective solutions and meticulous after-sales service. We firmly believe that: we're outstanding as we have been specialized.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.