Electromagnetic Flow Meter Electrode

Electromagnetic Flow Meter Electrode

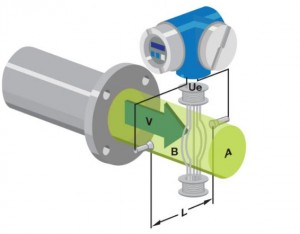

The electromagnetic flowmeter electrode is an important part of the electromagnetic flowmeter and is used to measure the conductivity and flow rate of the fluid.

Electrodes are usually made of conductive materials, such as stainless steel, titanium alloy, etc., with good conductivity and corrosion resistance, and can accurately measure current signals in fluids and convert them into corresponding flow signals.

Choosing a suitable electrode material can not only ensure the accuracy of the measurement results but also prevent the electromagnetic flowmeter from being damaged by fluid corrosion. Our tantalum-stainless steel composite electrodes are more likely to meet your measurement needs and are cheap.

Electrode Information

| Product Name | Electromagnetic Flow Meter Electrode |

| Available Material | Tantalum, HC276, Titanium, SS316L |

| Size | M3,M5, M8, etc. |

| MOQ | 20 pieces |

| Note: Support customization according to drawings | |

Common Electrode Material Applications

| Electrode Material | Application |

| Stainless steel SS316L | It is suitable for weak corrosive fluids such as water and sewage and is widely used in petroleum, chemical industry, urea industry, and other industries. |

| Hastelloy B(HB) | It has strong corrosion resistance to hydrochloric acid of any concentration below the boiling point and is also resistant to non-oxidizing acids, alkali, and non-oxidizing salt solutions such as sulfuric acid, phosphate, hydrofluoric acid, and organic acids. |

| Hastelloy C(HC) | Resistant to corrosion by oxidizing acids such as nitric acid and mixed acids, as well as corrosion by oxidizing salts such as Fe3+ and Cu2+ or liquids containing oxidizing agents such as hypochlorite solutions and seawater. |

| Titanium (Ti) | Suitable for seawater, various chlorides, hypochlorites, oxidizing acids (including fuming nitric acid), organic acids, alkalis, etc. Not resistant to corrosion by pure reducing acids (such as sulfuric acid, and hydrochloric acid). However, if the acid contains oxidants (such as Fe3+, and Cu2+), the corrosion will be greatly reduced. |

| Tantalum (Ta) | In addition to hydrofluoric acid, fuming sulfuric acid, and strong alkalis, it can resist almost all chemicals, including boiling hydrochloric acid. |

| Platinum-iridium alloy | Applicable to almost all chemical media except aqua regia and ammonium salt. |

| Stainless steel-coated tungsten carbide | Suitable for non-corrosive, highly abrasive fluids. |

| Note: Since there are many types of media and their corrosiveness changes due to complex factors such as temperature, concentration, flow rate, etc., this table is for reference only. Users should make their own choices based on actual conditions, and conduct corrosion resistance tests on the selected materials if necessary. | |

Do you want to know more about our products?

Contact Us

Amanda│Sales Manager

E-mail: amanda@winnersmetals.com

Phone: +86 156 1977 8518(WhatsApp/Wechat)

If you want more details and prices of our products, please contact our sales manager, she will reply as soon as possible (usually no more than 24h), thank you.