Cheapest Factory Moly Rod - TZM MoLa MHC Molybdenum alloy rod bars – WINNERS

Cheapest Factory Moly Rod - TZM MoLa MHC Molybdenum alloy rod bars – WINNERS Detail:

Product Description

Molybdenum alloy

Molybdenum alloy has the characteristics of molybdenum, and on this basis is better than pure molybdenum. We can produce and process all three molybdenum alloys.

TZM

TZM alloy is the most excellent molybdenum alloy high temperature material at present. It is a solid solution hardening and particle reinforced molybdenum based alloy. TZM is harder than pure molybdenum metal, with higher recrystallization temperature and better creep resistance. Recrystallization temperature is about 1400°C, much higher than molybdenum. It can provide better weldability.

MHC

MHC is a particle reinforced molybdenum alloy containing hafnium and carbon. Due to the uniform distribution of ultra fine carbides, the material still exhibits excellent heat resistance and creep resistance at 1550°C, and the recommended maximum operating temperature is also 150°C higher than that of TZM. For example, in extrusion dies it can withstand extreme thermal and mechanical loads, so MHC materials are recommended for metal forming applications.

MoLa

The addition of rare earth elements in Mo La alloy can not only improve the recrystallization temperature and high temperature creep resistance of molybdenum, but also significantly reduce the plastic brittle transition temperature of molybdenum, increase plasticity, improve the room temperature brittleness and high temperature drop resistance of molybdenum.

What products can we provide

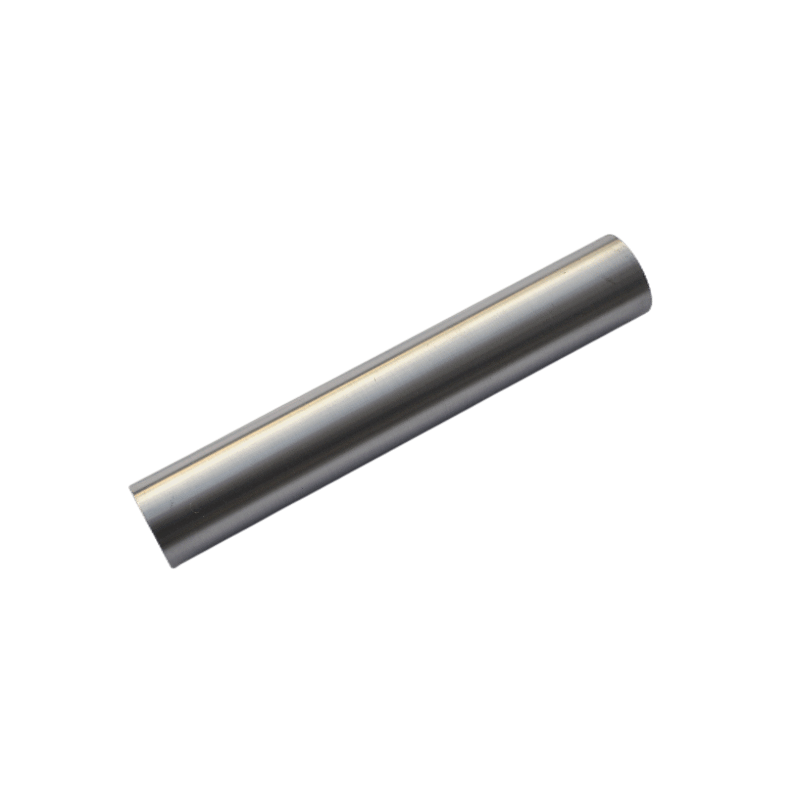

■ Molybdenum Alloy Rods

■ Molybdenum alloy sheet

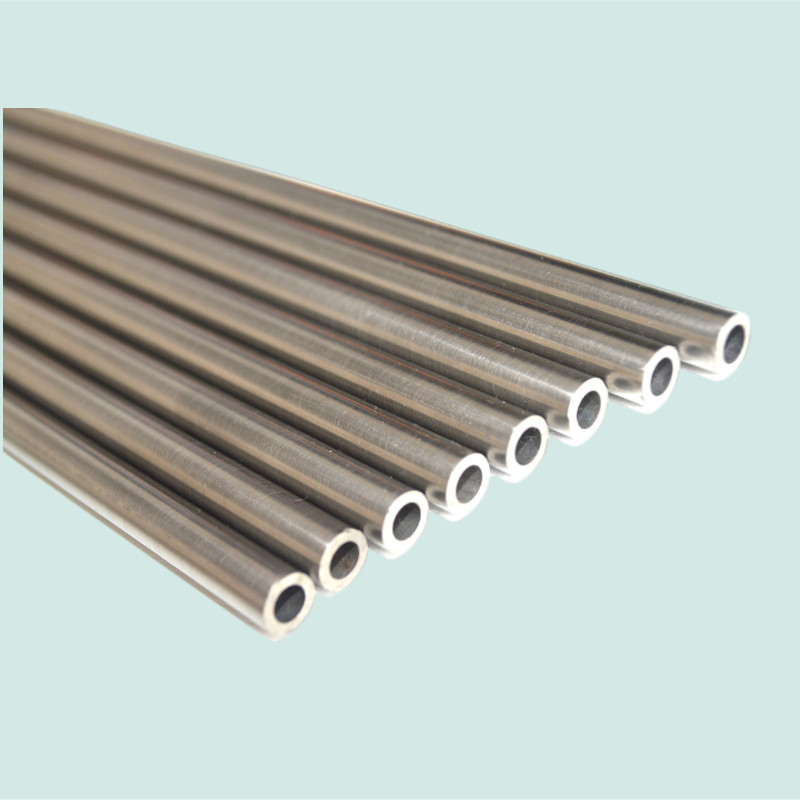

■ Molybdenum alloy pipe

■ Molybdenum alloy processing parts

Product Parameters

|

Type |

Thickness(mm) | Width(mm) | Length(mm) |

| Plate |

0.1~12 |

160~450 | 600~1500 |

| Bar |

Φ4-120 |

5-1200 | |

| Round plate |

Φ20-600 |

6-25 | |

*If the size you need is not in this form, please contact us and we will get back to you as soon as possible.

Application

■ TZM alloy is used as nozzle material, gas distribution valve body, gas pipe pipeline material, grid material in electronic tube, X-ray rotating anode parts, die-casting mold and extrusion mold, heating element and heat insulation in high temperature furnace screen etc.

■ MHC materials are recommended for metal forming applications such as extrusion dies which can withstand extreme thermal and mechanical loads.

■ Rare earth wire is mainly used as electric light source filament, EDM electrode and high temperature furnace heating element, etc.

■ Rare earth molybdenum plates and sheets are used as wafers for stamping into thyristors, as well as heat shields and guide sheets for electronic tubes.

■ Rare earth molybdenum alloy can be used as high-quality steel hot perforation head, as well as aerospace and nuclear industry materials, X-ray pole targets, die-casting dies and extrusion dies.

■ Rare earth molybdenum shaped products are used as glass melting electrodes, rare earth smelting electrodes, crucibles, high temperature sintering boats, high temperature radiation heat shields, flow ports, guide rails, pads, etc.

Order Information

Inquiries and orders should include the following information:

☑ Material

☑ Dimensions of the Molybdenum alloy or drawing

☑ Quantity

Product detail pictures:

Related Product Guide:

We insist about the theory of growth of 'High excellent, Performance, Sincerity and Down-to-earth working approach' to offer you with great company of processing for Cheapest Factory Moly Rod - TZM MoLa MHC Molybdenum alloy rod bars – WINNERS , The product will supply to all over the world, such as: Gambia, Sydney, America, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!