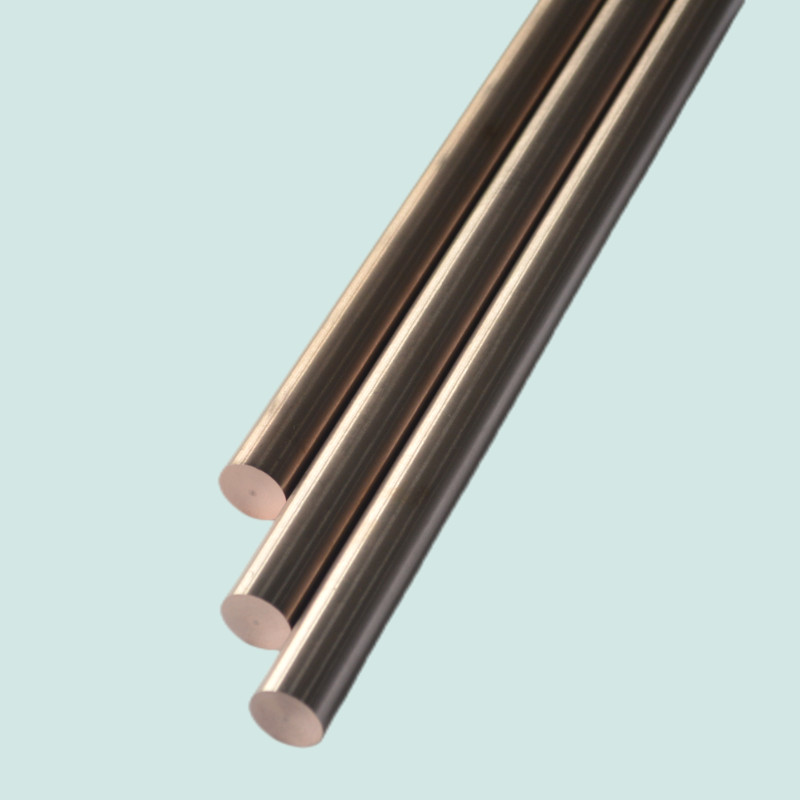

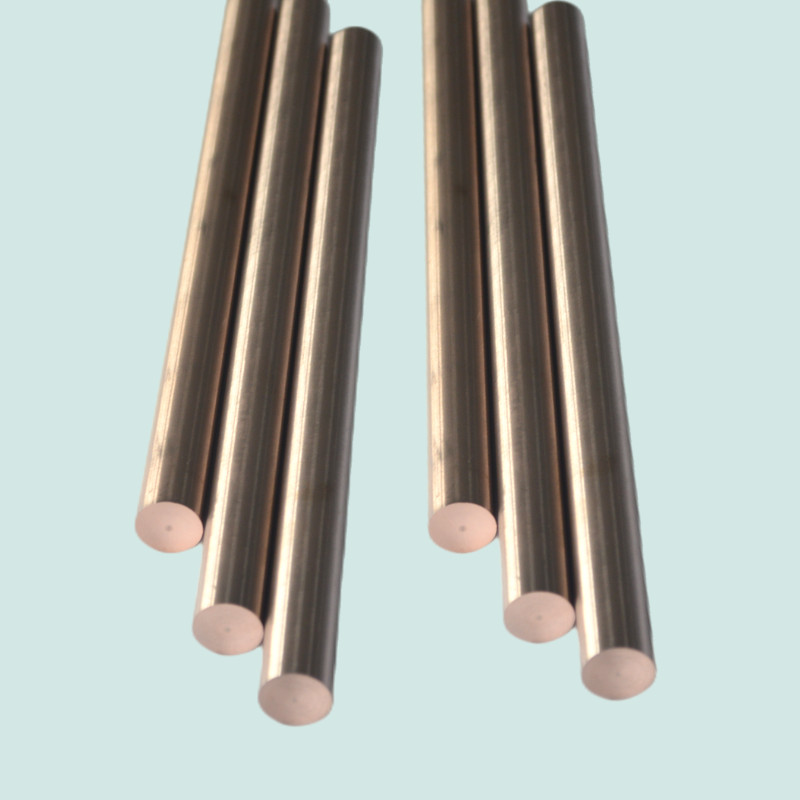

Best quality Moly Rod For Glass Melting - Tungsten copper alloy rods bars supplier – WINNERS

Best quality Moly Rod For Glass Melting - Tungsten copper alloy rods bars supplier – WINNERS Detail:

Product Description

Tungsten copper alloy combines the advantages of copper and tungsten, high strength, high specific gravity, high temperature resistance, arc ablation resistance, good electrical conductivity, good processing performance. High-quality tungsten powder and oxygen-free copper powder are used, and isostatic pressing (high temperature sintering-copper infiltration) is used to ensure product purity and accurate ratio, fine structure and excellent performance. Good arc breaking performance, good electrical conductivity, good thermal conductivity and small thermal expansion.

Product Parameters

Physical Properties of Tungsten and Copper

|

Material |

Density (g/cm3) |

Thermal expansion coefficient 10-6/℃ |

Thermal conductivity w/(m·k) |

Heat capacity J/(kg·℃) |

Elastic Modulus GPa |

Poisson density |

Melting point °C |

Strength MPa |

|

W |

19.3 |

4.5 |

174 |

136 |

411 |

0.28 |

3410 |

550 |

|

Cu |

8.93 |

16.6 |

403 |

385 |

145 |

0.34 |

1083 |

120 |

Grade of the Tungsten copper alloy

|

Grade |

Density(g/cm3) |

Application |

|

WCu7 |

17.3~17.8 |

Nozzle, gas rudder |

|

WCu10 |

16.8~17.3 |

Nozzle, gas rudder |

|

WCu15 |

16.0~16.5 |

Terminals, components, barium salt electron cathode |

|

WCu20 |

15.1~15.5 |

contacts, electrodes |

|

WCu30 |

13.7~14.2 |

Contacts, electrodes, medicine caps |

|

WCu40 |

12.7~13.2 |

contacts, electrodes |

|

WCu50 |

11.7~12.2 |

contacts, electrodes |

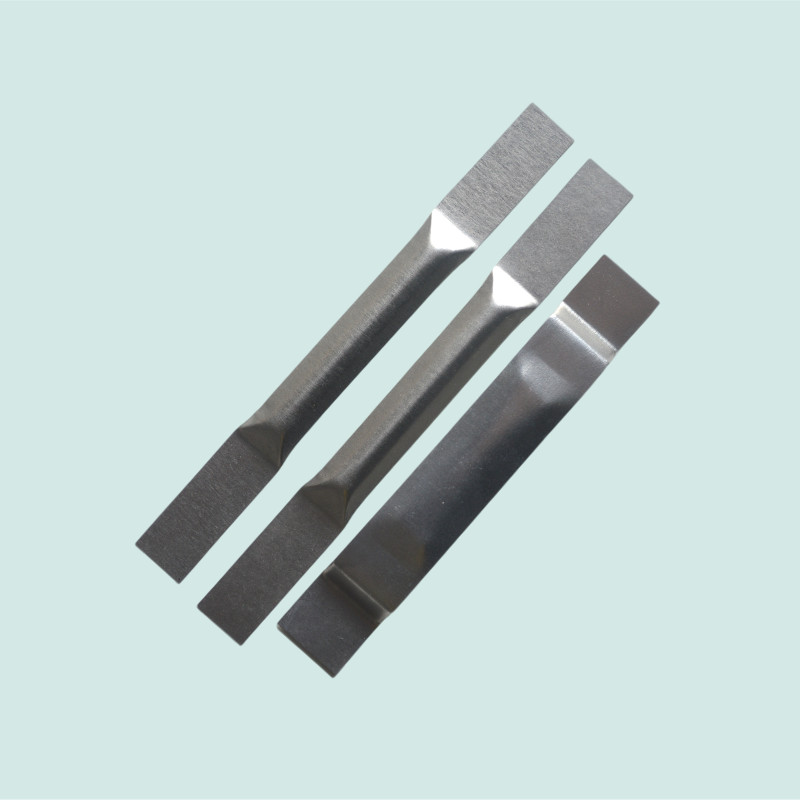

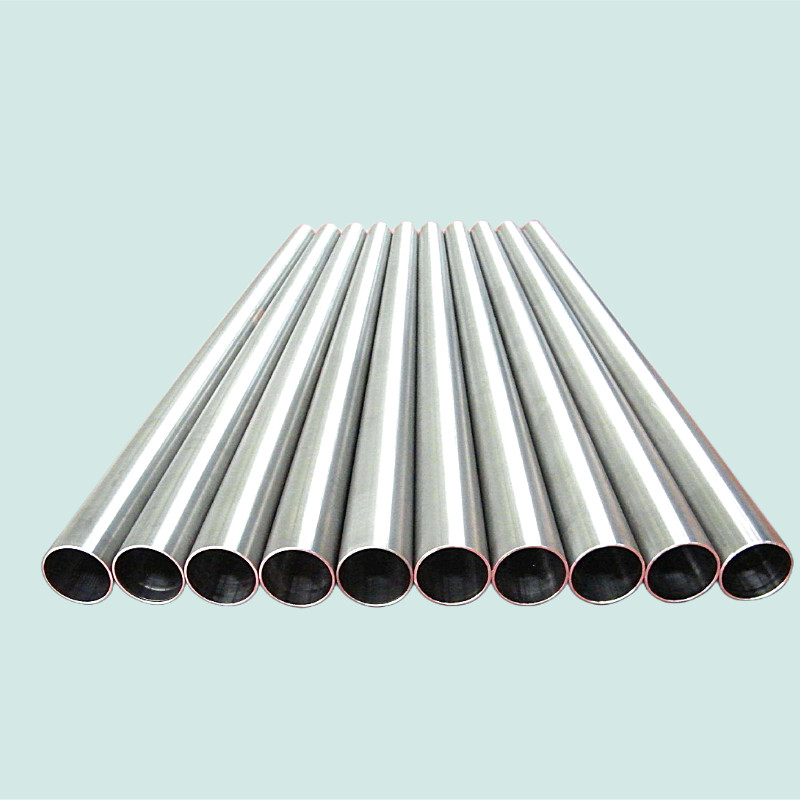

Application

● Manufacture of arc ablation resistant high voltage electrical switch contacts and rocket nozzle throat linings.

● High temperature components such as rudder.

● Electrodes for electrical machining.

● High temperature molds and other occasions requiring electrical and thermal conductivity and high temperature use.

Order Information

Inquiries and orders should include the following information

● Composition ratio of tungsten and copper

● Diameter and Length

● Quantity

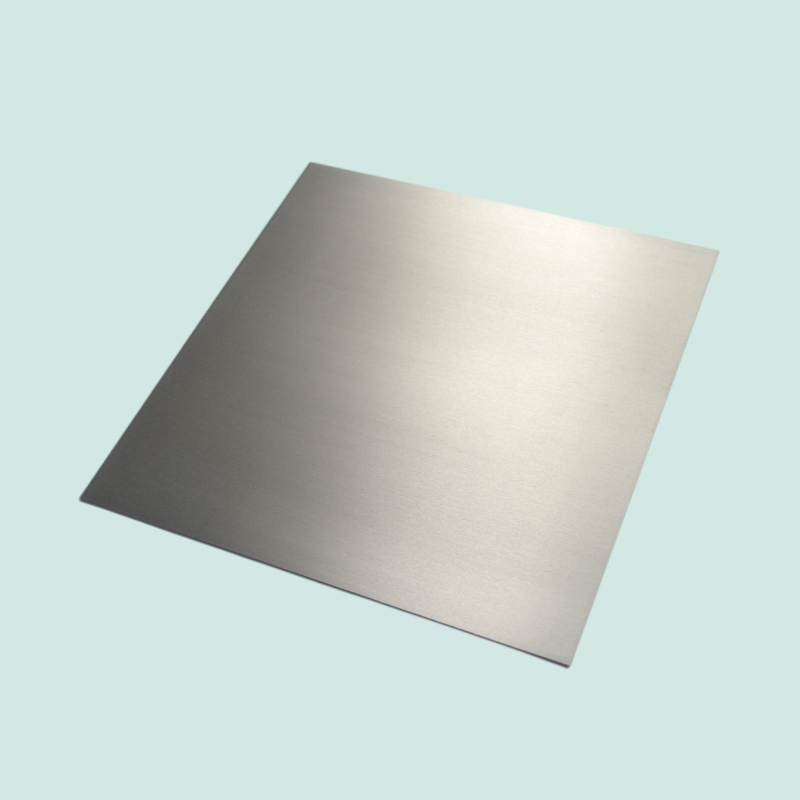

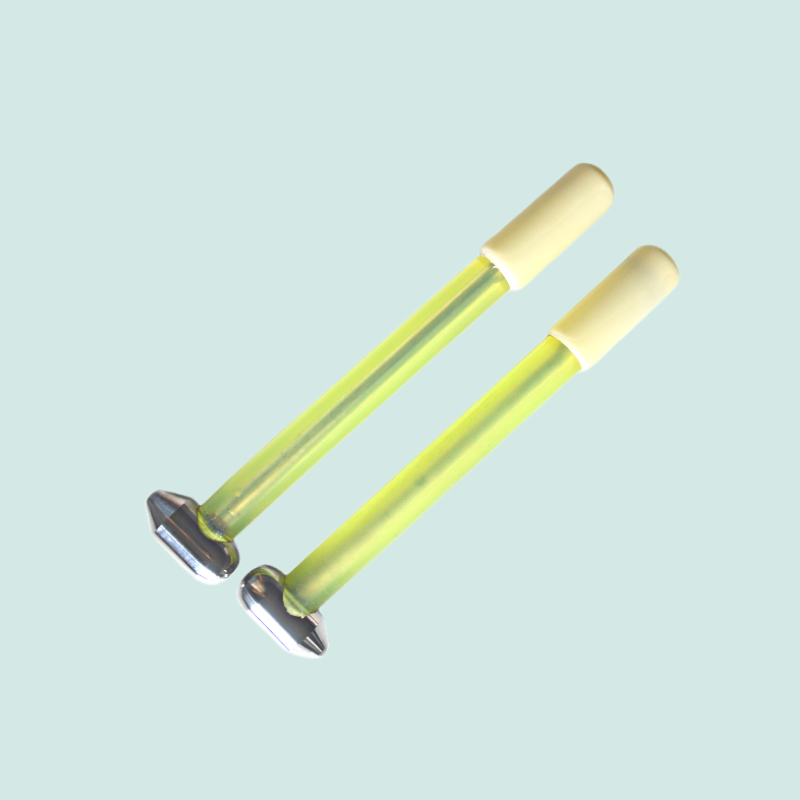

Product detail pictures:

Related Product Guide:

It is our responsibility to meet your needs and efficiently serve you. Your satisfaction is our best reward. We are looking forward to your visit for joint growth for Best quality Moly Rod For Glass Melting - Tungsten copper alloy rods bars supplier – WINNERS , The product will supply to all over the world, such as: Albania, Nairobi, New Orleans, With the aim of "compete with good quality and develop with creativity" and the service principle of "take customers' demand as orientation", we will earnestly provide qualified products and good service for domestic and international customers.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!