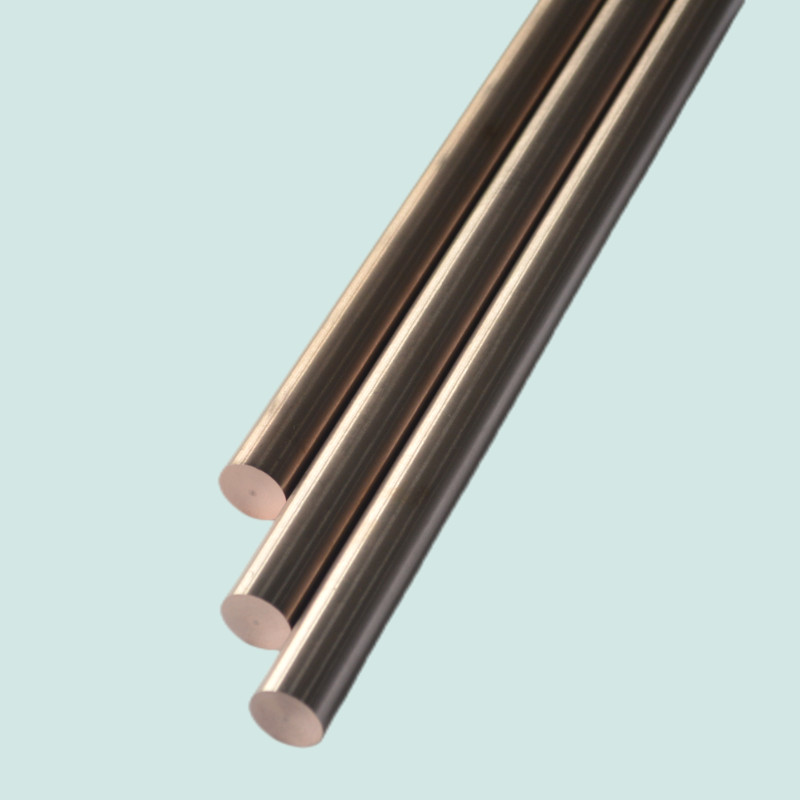

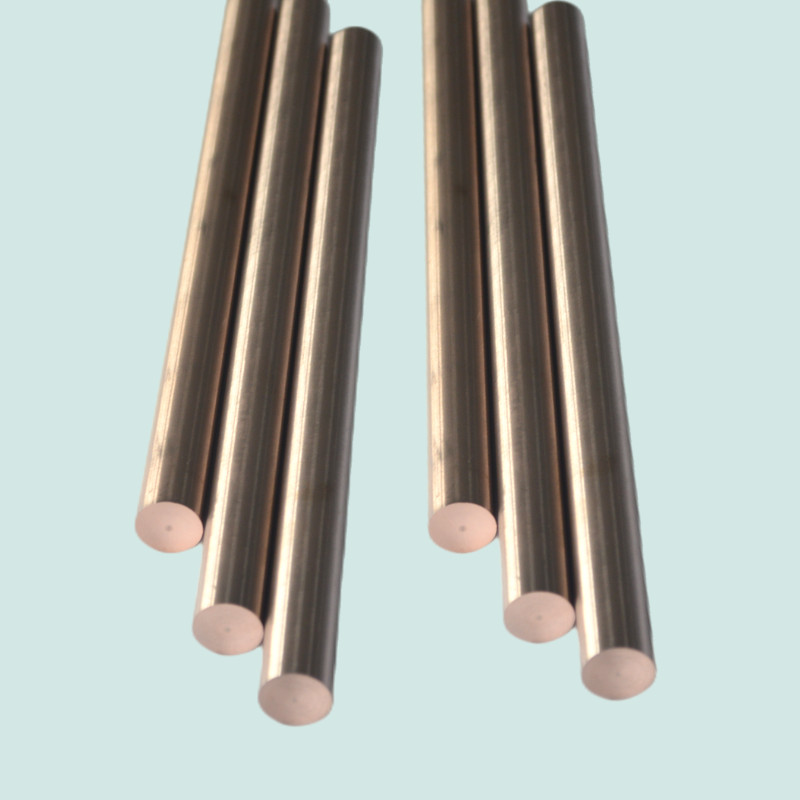

Best quality Moly Rod For Glass Melting - Tungsten copper alloy rods bars supplier – WINNERS

Best quality Moly Rod For Glass Melting - Tungsten copper alloy rods bars supplier – WINNERS Detail:

Product Description

Tungsten copper alloy combines the advantages of copper and tungsten, high strength, high specific gravity, high temperature resistance, arc ablation resistance, good electrical conductivity, good processing performance. High-quality tungsten powder and oxygen-free copper powder are used, and isostatic pressing (high temperature sintering-copper infiltration) is used to ensure product purity and accurate ratio, fine structure and excellent performance. Good arc breaking performance, good electrical conductivity, good thermal conductivity and small thermal expansion.

Product Parameters

Physical Properties of Tungsten and Copper

|

Material |

Density (g/cm3) |

Thermal expansion coefficient 10-6/℃ |

Thermal conductivity w/(m·k) |

Heat capacity J/(kg·℃) |

Elastic Modulus GPa |

Poisson density |

Melting point °C |

Strength MPa |

|

W |

19.3 |

4.5 |

174 |

136 |

411 |

0.28 |

3410 |

550 |

|

Cu |

8.93 |

16.6 |

403 |

385 |

145 |

0.34 |

1083 |

120 |

Grade of the Tungsten copper alloy

|

Grade |

Density(g/cm3) |

Application |

|

WCu7 |

17.3~17.8 |

Nozzle, gas rudder |

|

WCu10 |

16.8~17.3 |

Nozzle, gas rudder |

|

WCu15 |

16.0~16.5 |

Terminals, components, barium salt electron cathode |

|

WCu20 |

15.1~15.5 |

contacts, electrodes |

|

WCu30 |

13.7~14.2 |

Contacts, electrodes, medicine caps |

|

WCu40 |

12.7~13.2 |

contacts, electrodes |

|

WCu50 |

11.7~12.2 |

contacts, electrodes |

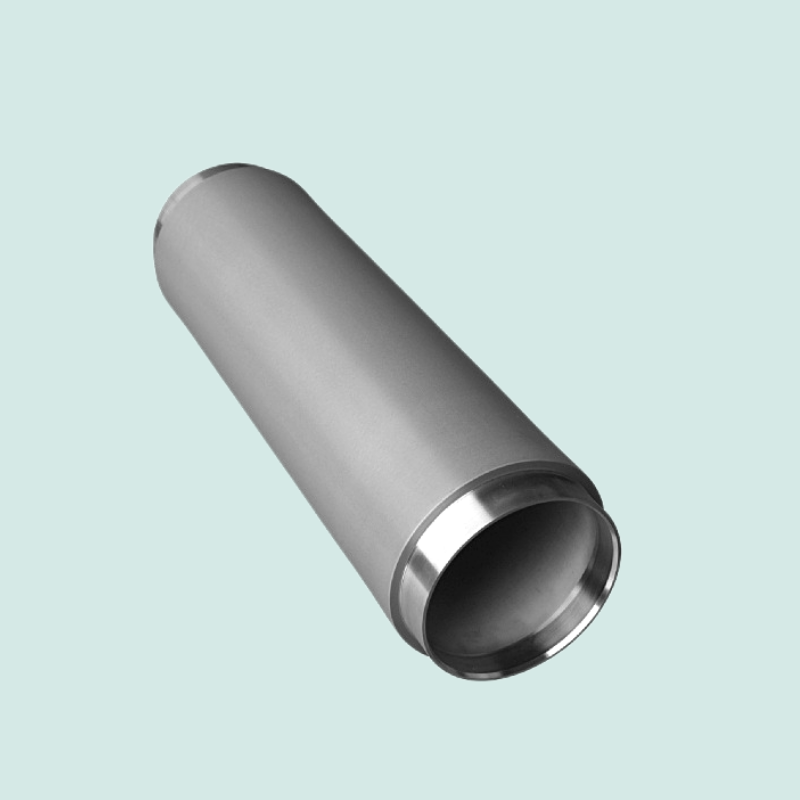

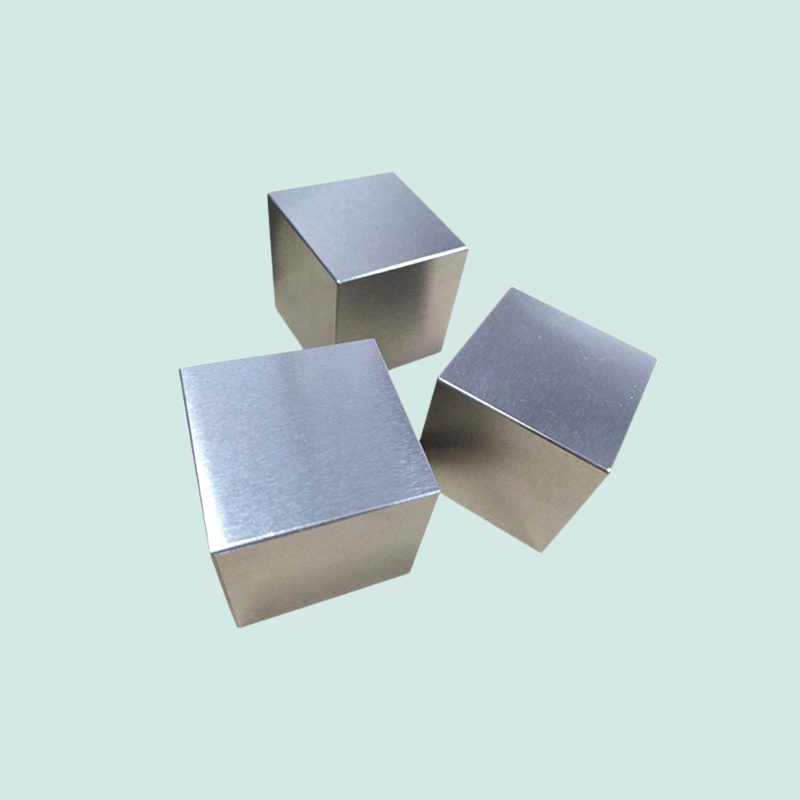

Application

● Manufacture of arc ablation resistant high voltage electrical switch contacts and rocket nozzle throat linings.

● High temperature components such as rudder.

● Electrodes for electrical machining.

● High temperature molds and other occasions requiring electrical and thermal conductivity and high temperature use.

Order Information

Inquiries and orders should include the following information

● Composition ratio of tungsten and copper

● Diameter and Length

● Quantity

Product detail pictures:

Related Product Guide:

Now we have superior devices. Our solutions are exported to your USA, the UK and so on, enjoying a superb name between customers for Best quality Moly Rod For Glass Melting - Tungsten copper alloy rods bars supplier – WINNERS , The product will supply to all over the world, such as: Amman, Oman, Iraq, We will initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!