100% Original Molybdenum Bolts - Pure Molybdenum Crucible for Rare Earth Smelting – WINNERS

100% Original Molybdenum Bolts - Pure Molybdenum Crucible for Rare Earth Smelting – WINNERS Detail:

Product Description

Molybdenum Crucible

The melting point of molybdenum is as high as 2610°C. Therefore, tungsten crucibles are widely used as core containers in industrial furnaces such as sapphire single crystal growth furnaces, quartz glass melting furnaces, and rare earth melting furnaces. The long-term working temperature is generally between 1200°C and 1800°C.

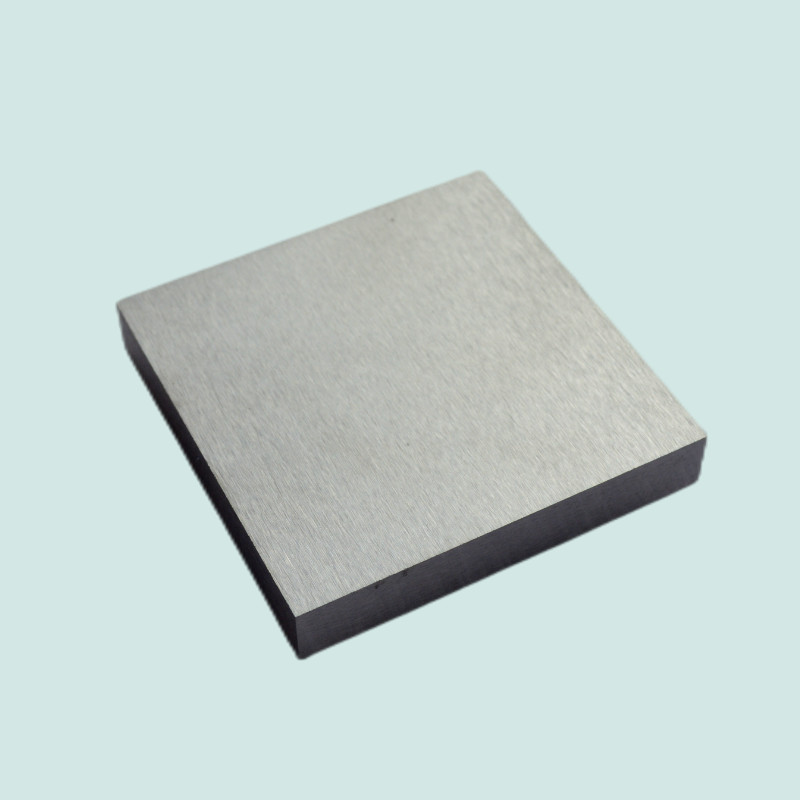

Molybdenum crucibles with high purity, high density, no internal cracks, precise dimensions, and smooth inner and outer walls are particularly important for sapphire single crystal growth furnaces. High-quality molybdenum crucibles play a key role in the success rate of seed crystals, quality control of crystal pulling, and service life during the growth of sapphire crystals.

Product Parameters

|

Products name |

Molybdenum crucibles |

|

Standard |

GB/T3462-2007 |

|

Grade |

Mo1 |

|

Purity |

≥99.95% |

|

Type |

Spinning Crucible, Machined Crucible, Welding Crucible |

|

MOQ |

1 piece or 1 set |

|

Surface |

Silver grey metal luster |

|

Operating temperature |

1200~1800℃ |

*Note: various sizes of molybdenum crucibles can be processed and customized according to customer requirements, and the high-precision requirements of users can be met through machining.

Molybdenum Crucible Process

Molybdenum powder→Sieving→Batching→Isostatic pressing→Rough turning processing→

Intermediate frequency sintering→Exquisite lathe processing

Application

■ Sapphire single crystal growth furnace. ■ Quartz glass melting furnace. ■ Rare earth smelting furnace.

Order Information

Inquiries and orders should include the following information:

■ Outer diameter, wall thickness, height of Moly crucibles.

■ Customized parts provide drawings or sample processing.

■ Select the crucible according to the actual needs.

Product detail pictures:

Related Product Guide:

owing to excellent assistance, a variety of top of the range items, aggressive costs and efficient delivery, we take pleasure in a very good standing amongst our shoppers. We've been an energetic corporation with wide market for 100% Original Molybdenum Bolts - Pure Molybdenum Crucible for Rare Earth Smelting – WINNERS , The product will supply to all over the world, such as: Adelaide, The Swiss, Ghana, Faced with the vitality of the global wave of economic integration, we've been confident with our high-quality items and sincerely service to all our customers and wish we can cooperate with you to create a brilliant future.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly